-

- Contact Us

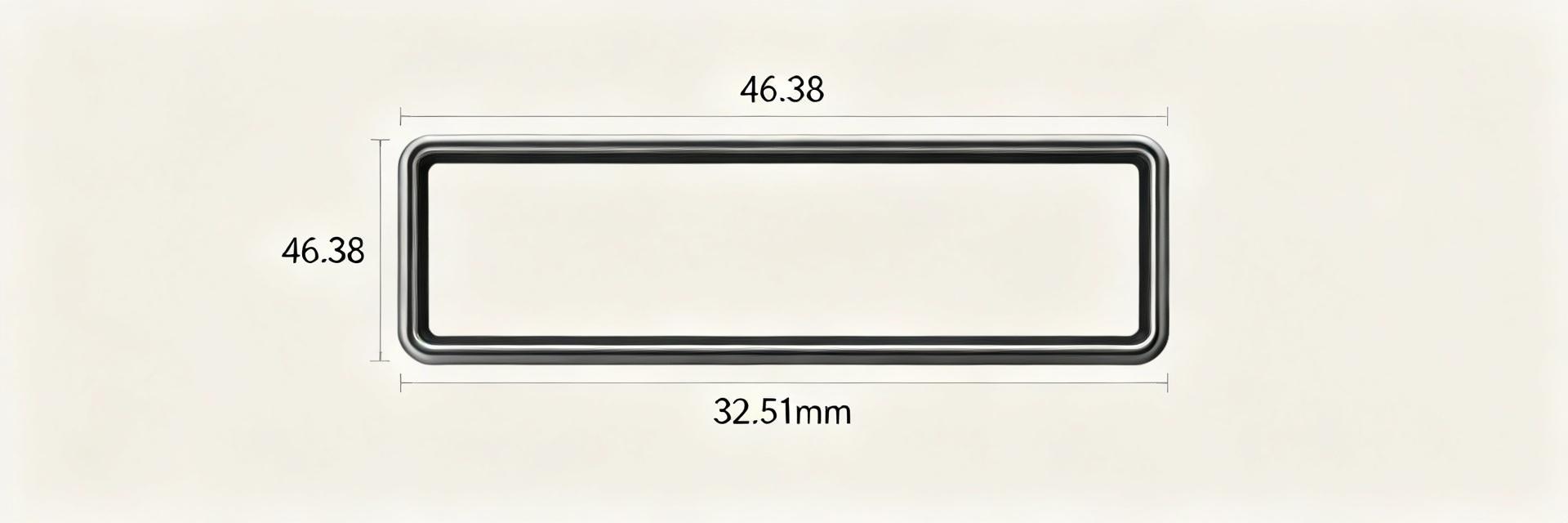

DMS-BZL3-C: Exact Dimensions & Sourcing Snapshot Guide

Precise panel bezel dimensions drive first-pass fit success and reduce procurement risk; the authoritative outside dimensions listed on the datasheet are 46.38 mm × 32.51 mm, and typical bezel tolerances fall in the ±0.2–0.5 mm range for cosmetic and non-critical clearances. Fast, verified sourcing matters because incorrect parts or undocumented lots cause rework and lead-time slips; this guide focuses on the exact measurements to trust and a practical sourcing checklist that lowers risk while keeping production on schedule.

1 — Part overview & key specs (background introduction)

What this part is and where it fits

This molded screen bezel is a panel-mount cosmetic and retention component designed for DMS-style panel meters and related displays. Typical use cases include direct replacement, retrofit upgrades, or inclusion in new panel designs where visible finish and mounting interface must match the instrument family. Review the bezel dimensions and cutout requirements early in mechanical layouts to avoid late-stage redesigns.

Quick spec snapshot (what to pull from the datasheet)

When extracting data from the manufacturer datasheet, capture each parameter with units and tolerance. The table below is the recommended two-column writer format to present in documentation; always cite the manufacturer datasheet as the authoritative source for final verification.

| Parameter | Value (Units) / Typical Tolerance |

|---|---|

| Outside dimensions | 46.38 × 32.51 mm / ±0.10–0.20 mm |

| Recommended panel cutout | See datasheet cutout drawing / ±0.20–0.50 mm |

| Bezel thickness & lip | Typical 1.5–2.5 mm / ±0.2 mm |

| Mounting hole pattern | Pitch & diameter per drawing (mm) / ±0.1–0.3 mm |

| Insertion depth / flange depth | Specified on datasheet / ±0.5 mm |

| Weight | ~2–6 g (estimate) / N/A |

| Operating temperature | Per datasheet (°C) |

| Sealing / gasket | Gasket present or not (yes/no); compression spec if present |

2 — Exact dimensions & panel cutout guide (data analysis)

Dimension checklist (values, tolerances, units)

Critical measurements to capture in CAD and drawings: outside dims (46.38 × 32.51 mm), recommended panel cutout dims (follow datasheet callouts), bezel lip projection, flange depth, mounting hole pitch and diameter, and insertion depth into the panel. Use millimeters as primary units and annotate dual units if needed. Recommended tolerances: ±0.2 mm nominal for cosmetic mating surfaces, ±0.5 mm for non-critical clearances; annotate CAD with tolerance callouts and balloon numbers tied to the datasheet.

Cutout & mounting best practices

Prepare cutouts on a flat fixture, deburr all edges, and verify the nominal size with calibrated calipers. Produce a rapid 3D-printed prototype to test fit—allow gasket compression of 0.5–1.0 mm if specified. For screw-mounted bezels, follow the datasheet torque guidance when present; otherwise use low torque to avoid plastic deformation. Include front view, side section, and mounting hole detail in assembly drawings with material callouts and finish notes.

3 — Compatibility, alternatives & cross-reference method (method/guideline)

Finding interchangeable bezels and cross-referencing

To identify interchangeable candidates, match these parameters: outside dimensions, cutout dimensions, mounting hole pattern, bezel thickness, and aesthetic features (color, finish). Build a comparison matrix with columns: Parameter → Target part → Candidate part → Pass/Fail; mark fails where differences exceed tolerance thresholds. For cosmetic swaps, ensure front-face alignment and visible gap remains within acceptable visual tolerances.

When to use an adapter or redesign

Use a simple bezel swap when dimension and mounting patterns fall within the specified tolerances. If differences exceed ±0.5 mm for mounting features or a gasket vs. non-gasket mismatch exists, plan for an adapter plate or panel redesign. Quick fixes include thin spacers or stamped adapter plates; caution: adapters can introduce water ingress paths or misalignment—validate with a prototyped assembly and functional environmental test where sealing is required.

4 — Sourcing snapshot & procurement channels (case / data)

Where to search (authorized channels, brokers, surplus) — without brand names

Search channels include: manufacturer datasheet/representative, authorized distributors, electronic component marketplaces, surplus/remarket suppliers, and local electronic hardware outlets. Useful query phrases: “panel bezel cutout 46.38x32.51 mm,” “DMS style panel bezel dimensions,” and “bezel cutout gasket panel mount.” Filter results by documented datasheet availability and clear packaging/lot info.

Verification, lead time & packaging data to request

Ask suppliers for the datasheet and a certificate of conformance, photos of the actual item (for brokers), stated RoHS/ECCN status, and lot or date-code traceability. Collect procurement metrics: typical lead time range (stock: days; special order: weeks), MOQ, and packaging format (bulk/tray/box). Request unit weight for shipping estimates and confirm part marking to prevent mis-shipments.

5 — Procurement checklist & quick action plan (action recommendation)

Pre-order checklist (what to confirm before purchase)

- Confirm exact part number (DMS-BZL3-C) against the datasheet and assembly drawing.

- Verify panel cutout compatibility on your latest CAD drawing and tolerance callouts.

- Confirm gasket presence and specified compression allowance if required for sealing.

- Request sample or prototype for fit verification before bulk order.

- Clarify lead time, MOQ, return policy, and certificate of conformance from the supplier.

On receipt — inspection & installation tips

Perform acceptance inspection by measuring critical dimensions with calipers, checking mounting hole locations, and visually inspecting for cosmetic defects. Test-fit the bezel to a sample panel and record fitment notes. For installation, seat the gasket uniformly, use hand-controlled torque drivers within recommended ranges, and document lot/serial info on receiving paperwork for future traceability and replacement ordering.

Key summary

- Trust the datasheet values for outside dimensions and cutout specs; extract these into your CAD with tolerance callouts to prevent surprises during assembly.

- Follow the dimension checklist (outside dims, cutout, flange depth, hole pitch) and use ±0.2 mm for cosmetic fits, ±0.5 mm for non-critical clearances.

- Sourcing diligence—request datasheet, photos, CoC, and traceability—reduces procurement risk and prevents costly returns.

- Prototype-fit (3D print or sample) before bulk orders; inspect received parts dimensionally and document lot info for future replacements.

Frequently Asked Questions

How do I verify the DMS-BZL3-C cutout size before ordering?

Compare the datasheet cutout drawing to your panel CAD, produce a 3D-printed test piece or laser-cut test panel, and verify gasket compression allowance. Confirm measurements with calipers and check mounting hole alignment on the prototype before placing a bulk order — this prevents late-stage rework.

What tolerances should be applied to bezel dimensions in CAD?

Apply ±0.2 mm to critical visible and mating surfaces for cosmetic fit and ±0.5 mm to non-critical clearances. Clearly annotate these tolerances on the CAD drawing and reference the datasheet balloon callouts for each critical feature to maintain manufacturing consistency.

What procurement data should I request from a distributor or broker?

Request the official datasheet, certificate of conformance, photos of the actual item, RoHS/ECCN statement, lot/date-code traceability, stated lead time, MOQ, and packaging format. These items allow risk assessment and accurate logistics planning prior to purchase.

Summary

Verify the manufacturer datasheet dimensions (46.38 mm × 32.51 mm) and follow the cutout and tolerance guidance to ensure a reliable cosmetic and mechanical fit for DMS-BZL3-C. Use the sourcing checklist—datasheet, CoC, photos, lead time, and prototype-fit—to reduce procurement risk. Final rule: measure twice, verify supplier documentation, and prototype-fit before bulk ordering.

- Technical Features of PMIC DC-DC Switching Regulator TPS54202DDCR

- STM32F030K6T6: A High-Performance Core Component for Embedded Systems

- Tamura L34S1T2D15 Datasheet Breakdown: Key Specs & Limits

- PAL6055.700HLT Datasheet: Complete Technical Report

- FDP027N08B MOSFET Datasheet Deep-Dive: Key Specs & Test Data

- LT1074IT7: Complete Specs & Key Parameters Breakdown

- How to Verify G88MP061028 Datasheet and Specs - Checklist

- NFAQ0860L36T Datasheet: Measured IPM Performance Report

- 90T03P MOSFET: Complete Specs, Pinout & Ratings Digest

- 3386F-1-101LF Datasheet & Specs — Pinout, Ratings, Sources

-

MM74HC4050NSanyo Semiconductor/onsemiIC BUFFER NON-INVERT 6V 16DIP

MM74HC4050NSanyo Semiconductor/onsemiIC BUFFER NON-INVERT 6V 16DIP -

MM74HC4049NSanyo Semiconductor/onsemiIC BUFFER NON-INVERT 6V 16DIP

MM74HC4049NSanyo Semiconductor/onsemiIC BUFFER NON-INVERT 6V 16DIP -

MM74HC4040NSanyo Semiconductor/onsemiIC BINARY COUNTER 12-BIT 16DIP

MM74HC4040NSanyo Semiconductor/onsemiIC BINARY COUNTER 12-BIT 16DIP -

MM74HC4020NSanyo Semiconductor/onsemiIC BINARY COUNTER 14-BIT 16DIP

MM74HC4020NSanyo Semiconductor/onsemiIC BINARY COUNTER 14-BIT 16DIP -

MM74HC393NSanyo Semiconductor/onsemiIC BINARY COUNTR DL 4BIT 14MDIP

MM74HC393NSanyo Semiconductor/onsemiIC BINARY COUNTR DL 4BIT 14MDIP -

MM74HC374NSanyo Semiconductor/onsemiIC FF D-TYPE SNGL 8BIT 20DIP

MM74HC374NSanyo Semiconductor/onsemiIC FF D-TYPE SNGL 8BIT 20DIP -

MM74HC373NSanyo Semiconductor/onsemiIC D-TYPE TRANSP SGL 8:8 20DIP

MM74HC373NSanyo Semiconductor/onsemiIC D-TYPE TRANSP SGL 8:8 20DIP -

LT1213CS8Linear Technology (Analog Devices, Inc.)IC OPAMP GP 2 CIRCUIT 8SO

LT1213CS8Linear Technology (Analog Devices, Inc.)IC OPAMP GP 2 CIRCUIT 8SO -

MM74HC259NSanyo Semiconductor/onsemiIC LATCH ADDRESS 8BIT 16-DIP

MM74HC259NSanyo Semiconductor/onsemiIC LATCH ADDRESS 8BIT 16-DIP -

MM74HC251NSanyo Semiconductor/onsemiIC MULTIPLEXER 1 X 8:1 16DIP

MM74HC251NSanyo Semiconductor/onsemiIC MULTIPLEXER 1 X 8:1 16DIP