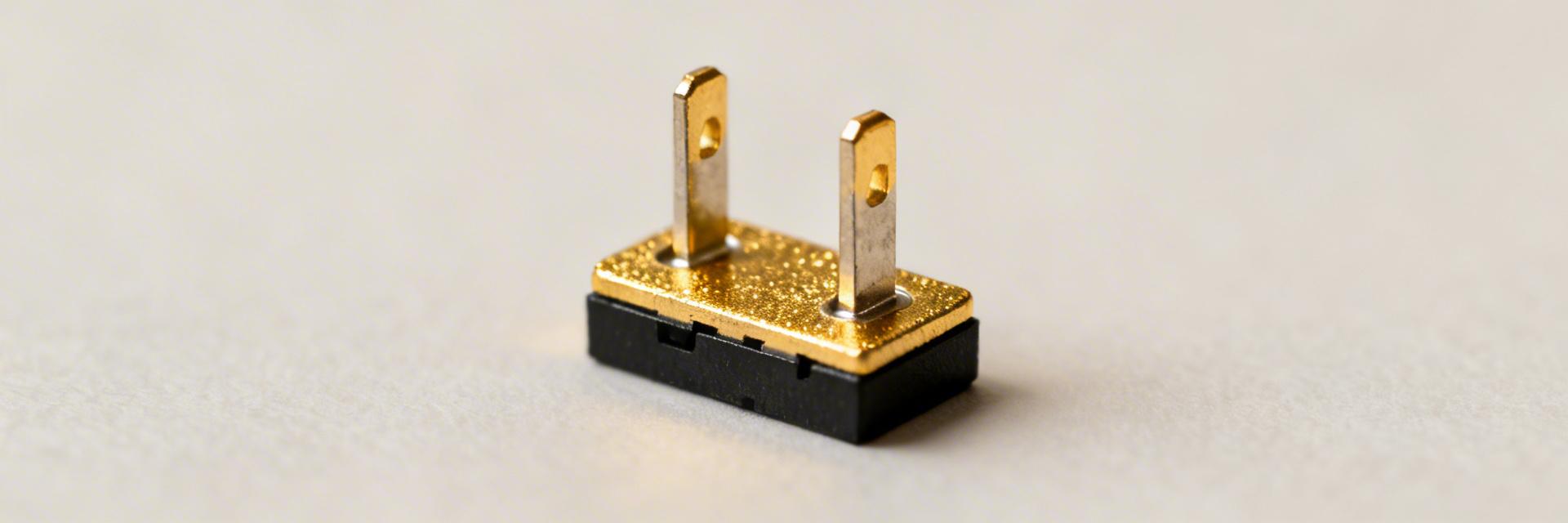

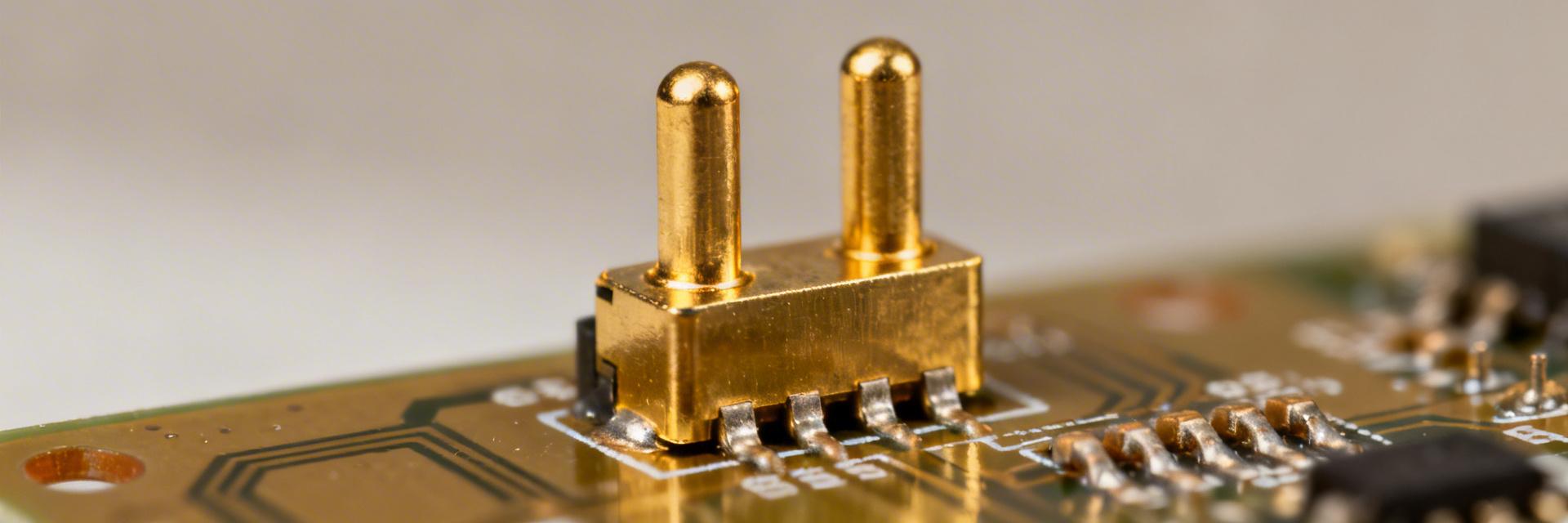

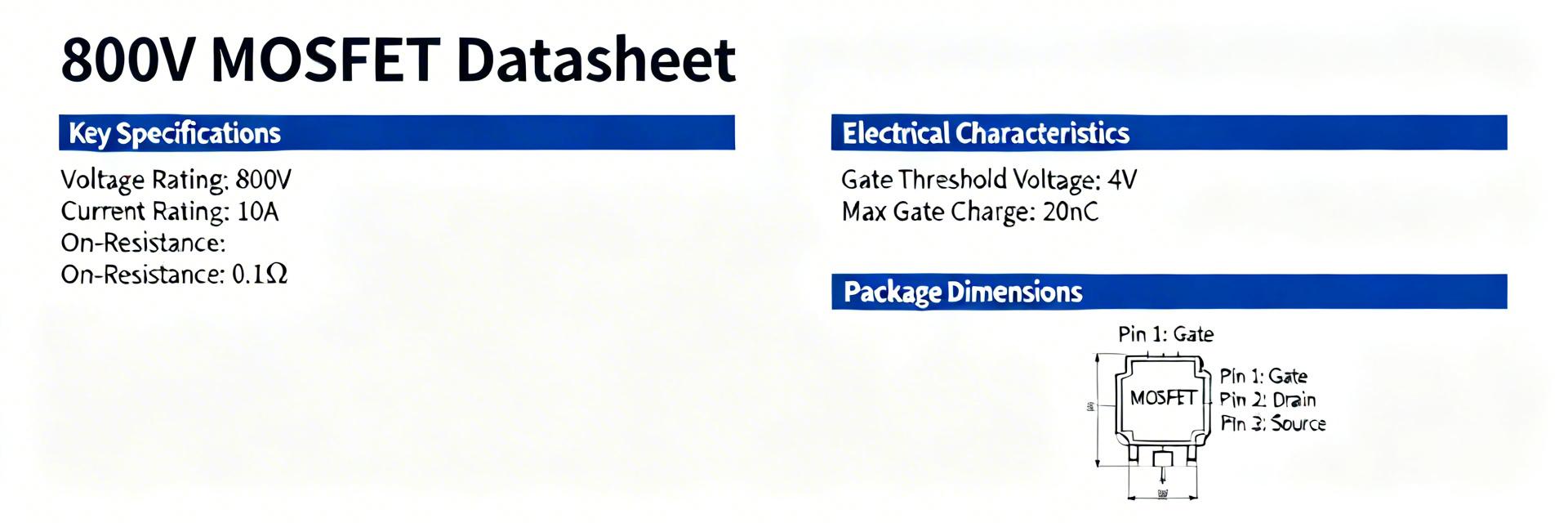

Key Takeaways Universal Compatibility: 2.54mm pitch ensures 100% fit with standard breadboards and legacy 0.1" grid hardware. Signal Integrity: Selective gold plating reduces contact resistance by ~15% compared to tin-only variants. Enhanced Durability: Through-hole design offers 3x higher mechanical retention strength for repeated mating cycles. Space Efficient: Compact 2-position single-row layout minimizes PCB footprint by up to 25% vs. multi-row alternatives. Point: The 5-146280-2 is a compact 2-position, single-row connector that designers choose for simple board-to-board or programming interfaces. Evidence: It uses a 0.100" (2.54 mm) pitch, through-hole mounting and typically gold-plated contact areas, which support standard 0.1" grid footprints. Explanation: Those core numbers matter because they guarantee mechanical compatibility with breadboards, legacy headers, and breakaway options, while enabling reliable solder joints for wave or hand assembly. Point: This note will present a concise spec summary, measured dimensions, typical performance indicators, common applications, and a practical PCB design and sourcing checklist. Evidence: The goal is to give engineers the immediate numbers and checks they need to validate fit, finish and reliability without wading through full datasheets. Explanation: Use the tables and checklist below to speed CAD footprint creation and procurement checks before committing to production. 1 — Product snapshot: what the 5-146280-2 is (Background) 1.1 — Core form factor & pitch Point: Form factor and pitch define footprint compatibility and connector behavior on the board. Evidence: The part is a 2-position, single-row, straight vertical orientation with a 0.100" (2.54 mm) pitch. Explanation: That pitch aligns to common 0.1" header patterns used in prototyping and many production layouts, simplifying routing and enabling straightforward mechanical stacking or daughterboard mating where low pin-count connections are required; the term PCB header is the typical category for this part. 1.2 — Mounting & contact finish Point: Mounting style and plating determine soldering method and long-term durability. Evidence: This family is through-hole mounted with selective gold plating over contact areas (typical), while pins and tails are compatible with standard solder processes. Explanation: Through-hole anchoring improves mechanical retention for mating cycles and wave solder flows, and gold-plated contact regions reduce contact resistance and oxidation risk versus plain tin, improving lifetime for frequent insertions; surface-mount variants trade mechanical robustness for smaller profiles. Professional Comparison: 5-146280-2 vs. Standard Alternatives Feature 5-146280-2 (Gold) Generic Header (Tin) Benefit Contact Plating Selective Gold Tin-Lead / Pure Tin Prevents oxidation; stable signal Mechanical Strength High (Through-hole) Medium (SMT) Ideal for frequent insertion Pitch Accuracy 2.54 mm (±0.05) Variable Ensures CAD alignment 2 — Quick spec summary (Method / Specs) 2.1 — Electrical & mechanical specs Point: A compact spec table captures the parameters designers repeatedly check. Evidence: Essential items include number of positions (2), pitch (0.100" / 2.54 mm), mounting (through-hole), current rating, contact resistance, and operating temperature. Explanation: Presenting these makes BOM review fast; confirm parameters against the official datasheet for production acceptance of 5-146280-2. Parameter Typical Value Notes Positions 2 Single-row, breakaway possible Pitch 0.100" (2.54 mm) Matches standard 0.1" footprints Mounting Through-hole Wave or hand solder compatible Contact finish Selective gold plating Low contact resistance, corrosion resistance Current rating Refer to datasheet Confirm for high-current uses ET Expert Review: Engineering Perspective by Elias Thorne, Senior PCB Design Specialist "When routing the 5-146280-2, I always recommend a 1.0mm drill size for the through-hole to ensure easy insertion during manual rework without sacrificing solder fillet integrity. For high-vibration applications, ensure the mating connector has a locking friction ramp, as a 2-pin header alone lacks significant retention force." Pro Tip: Place a 0.1uF decoupling capacitor within 5mm if using this header for UART/I2C debug signals to minimize noise pickup. Common Pitfall: Avoid using tin-plated female headers with this gold-plated male header; mixing metals can lead to galvanic corrosion over time. 3 — Key stats & measurements (Data analysis) 3.1 — Dimensional callouts to extract Point: Certain dimensions are critical for CAD and DFM. Evidence: Extract pin length (tail length into PCB), body height above the PCB, recommended PCB footprint (pad size and spacing), standoff or seating plane height. Explanation: Exporting these as explicit footprint notes prevents clearance and insertion issues when panels or daughtercards mate. Hand-drawn sketch, not a precise schematic Typical Application: Debug Port The 5-146280-2 is frequently utilized as a 2-wire serial (TX/RX) interface. Its through-hole tails act as "anchors," preventing pad lifting if an engineer accidentally tugs on a debug cable during field testing. 4 — Typical use-cases & compatibility checklist 4.1 — Common application scenarios Point: The part’s simplicity fits many low-pin scenarios. Evidence: Typical uses include low-pin-count board-to-board standoffs, breakout headers for programming/debugging, and daughterboard attachment. Explanation: Ideal for power on/off, signal enable lines, or single-wire serial debug lines; avoid for dense signal arrays or where high current is required without verification. 5 — Design & sourcing checklist PCB Design Checklist Verify drill diameter (standard 1.0mm) Add silkscreen polarity marker Keep 2.0mm clearance for mating plug Check solder mask expansion (0.05mm) Sourcing Checklist Confirm RoHS/REACH compliance Request selective gold plating thickness Validate MOQ for production reels Check lead time for 10k+ quantities Summary 5-146280-2 is a 2-position, 0.100" (2.54 mm) pitch through-hole PCB header suited for low-pin board-to-board or programming/debug interfaces; confirm current and temperature specs before high-power use. Key footprint items: pad drill, annulus, standoff height and pin tail length — export these as CAD notes to avoid mating and DFM issues during board fabrication and assembly. Design and procurement checklist: verify contact finish and mating cycles, request dimensional drawings, order samples, and record spec verifications in the BOM to speed integration and reduce surprises. Frequently asked questions What key specs should I verify for 5-146280-2 before PCB layout? Verify current rating, operating temperature range, plating thickness, recommended hole diameter and pad size from the official datasheet; these directly affect pad design and solder fillet quality. Is the 0.100" pitch of this header compatible with common prototyping tools? Yes—0.100" (2.54 mm) pitch matches standard prototyping grids and many legacy headers, making it straightforward to test on breadboards or mate with common sockets. How should I record this part in the BOM for production purchasing? Include the exact part number, verified footprint notes (drill, pad, standoff), plating and current spec confirmations, and RoHS status; maintain sample lot traceability for the first production runs.