L07P020D15 Current Sensor Datasheet: Deep Dive, Tests

2026-01-19 10:30:55

0

Typical open-loop Hall-effect current sensors aimed at the 20 A class advertise nominal ranges around 20 A, sub-microsecond to microsecond response times, and usable bandwidths up to 100 kHz; engineers therefore rely on datasheet-driven verification to ensure transient capture, thermal behavior, and isolation meet system requirements. This article parses the L07P020D15 datasheet, lays out reproducible test methods, summarizes expected measurements, and gives practical integration and purchasing guidance.

The goal is actionable: describe which datasheet claims to trust, how to test them on a bench with common instrumentation, what pass/fail tolerances to use, and integration notes for ADCs, filters and PCB layout. Primary references here are generic datasheet conventions and lab measurement practice rather than vendor commentary.

Overview: What the L07P020D15 current sensor is and where it fits

1.1 Key specifications at a glance

Point: The L07P020D15 is a board-mount Hall-effect open-loop current sensor specified for a nominal 20 A range with an analog voltage output and reinforced isolation. Evidence: The datasheet lists rated current, output scaling (V/A), bandwidth and isolation voltage fields. Explanation: Use the table below as a quick procurement checklist; items marked “verify” need bench confirmation (offset, bandwidth, temperature drift).

Parameter

Datasheet value (example)

Verify on bench?

Nominal current rating

20 A

No (confirm part number)

Topology

Hall-effect open-loop

No

Response time / Rise time

≤ 1 µs

Yes

Bandwidth

DC – 100 kHz

Yes

Isolation voltage

e.g., 2000 Vrms

Yes (if safety critical)

Output style

Voltage proportional to current (V/A)

No

Package

PCB-mount

Yes (footprint fit)

Nominal current (20 A)

Bandwidth (DC–100 kHz)

Rise time (≤1 µs)

Isolation (e.g., 2000 Vrms)

1.2 Sensor technology & operating principle

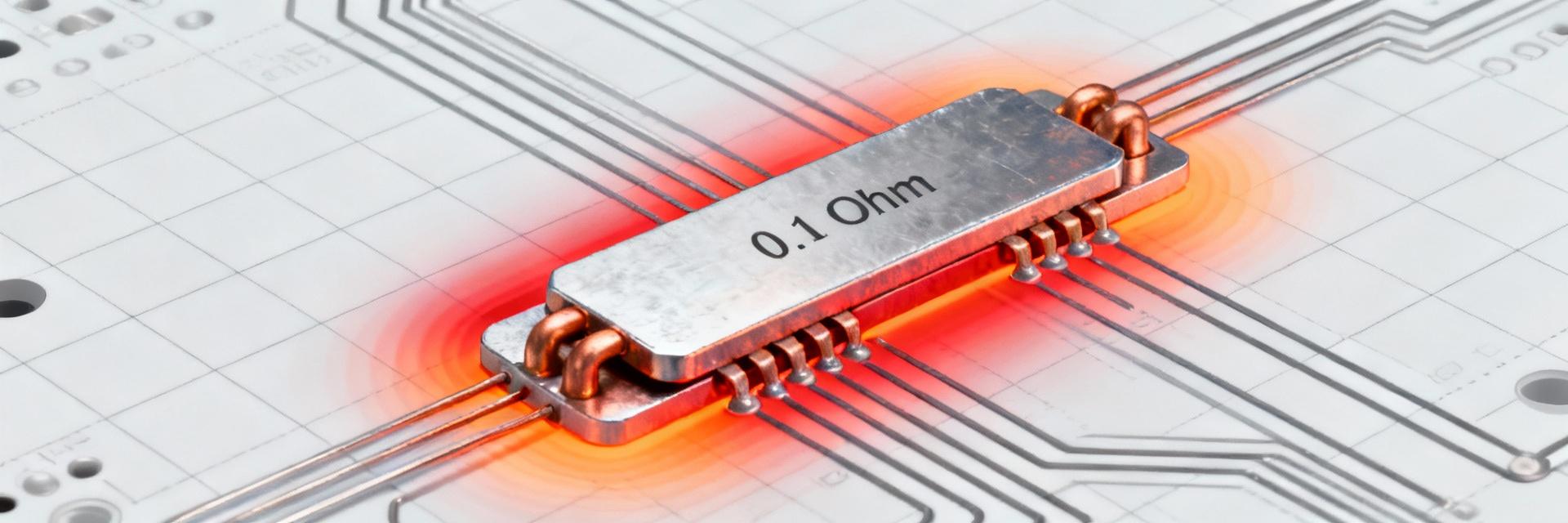

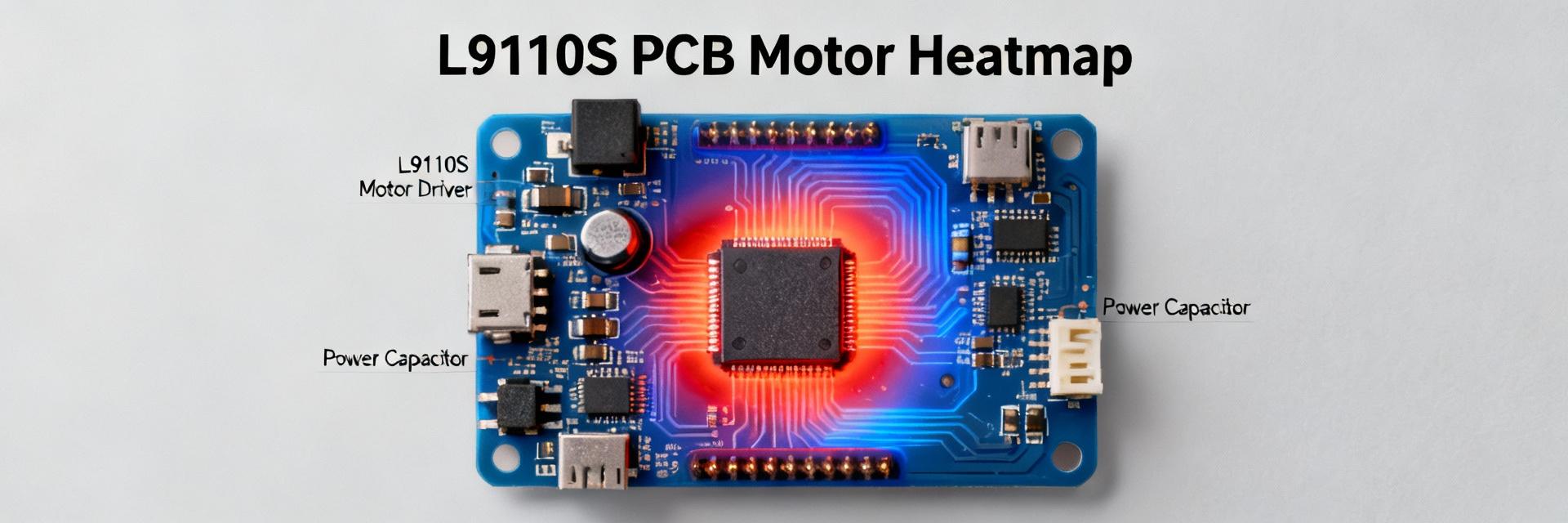

Point: The device uses an open-loop Hall-effect element positioned near a conductor; the magnetic field from conductor current produces an analog output. Evidence: Open-loop families trade lower cost and compact form factor for limited linearity and larger offset compared to closed-loop designs. Explanation: Best applications are power monitoring, motor drivers and battery management where bandwidth and isolation are required but ultra-high accuracy or very low offset are not the primary goals.

Datasheet deep-dive: interpreting electrical, mechanical & environmental specs

2.1 Electrical parameters explained (accuracy, bandwidth, response time, output scaling, isolation)

Point: Each electrical spec has practical implications: accuracy tolerances hide offset and gain error bands, bandwidth limits transient fidelity, and isolation ratings determine system creepage/clearance needs. Evidence: Datasheet accuracy often given as % of reading or % of full scale and accompanied by temperature coefficients and test conditions. Explanation: When reading the datasheet, note test conditions (ambient, RL, test frequency) and expect to verify offset at zero current, gain across the 0–20 A span, and bandwidth with a swept-frequency source; adopt tolerance bands of ±1% reading for gain and ±5 mA-equivalent for offset as initial acceptance criteria for this class.

2.2 Mechanical, thermal and compliance items

Point: Mechanical specs affect PCB cutout, mounting and safety. Evidence: Datasheet typically provides package outline, recommended PCB footprint, creepage/clearance numbers and maximum operating temperature. Explanation: Verify board cutout and standoff dimensions, confirm isolation class (basic vs reinforced), and plan mechanical fixation to avoid thermal cycling stress; if isolation is used in mains environments, insist on datasheet insulation class and re-check in procurement.

Test plan & measurement setup for L07P020D15

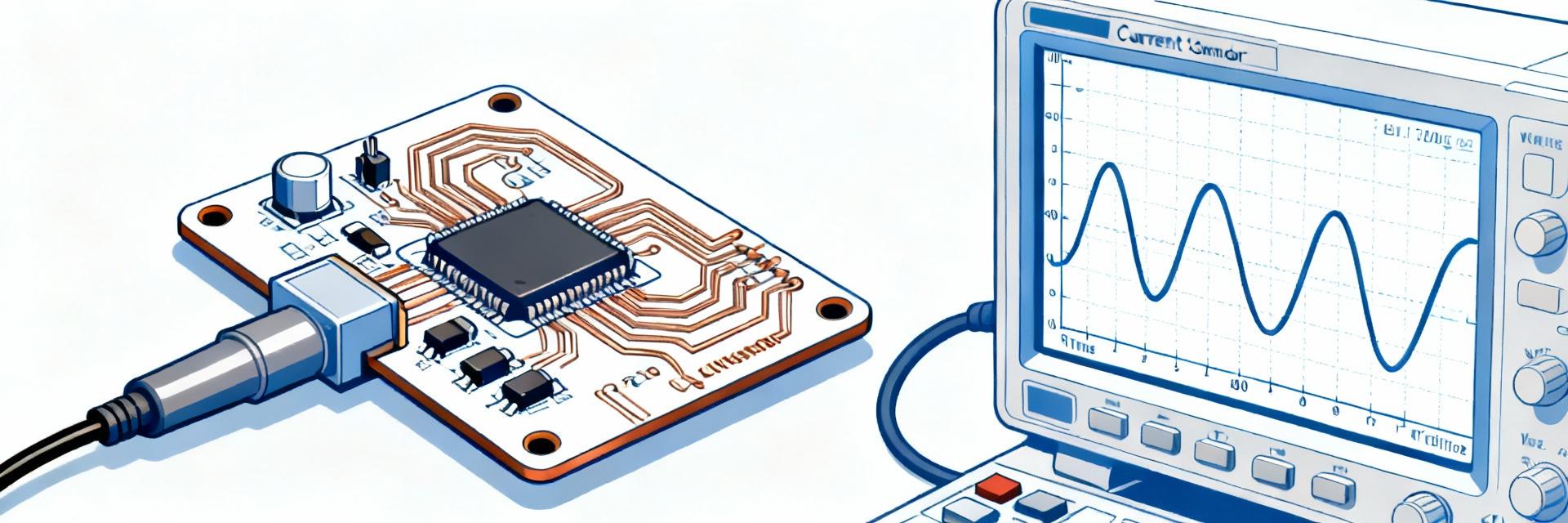

3.1 Test bench, instrumentation and wiring best practices

Point: Reliable measurements require a controlled bench: a low-noise programmable current source or precision source meter, an oscilloscope with ≥5× bandwidth headroom (e.g., 500 kHz scope for 100 kHz signals), and proper wiring. Evidence: Errors often originate from lead inductance, common-mode pickup and ground loops. Explanation: Use four-wire connections where possible, keep sense wiring short, use differential measurement across the sensor output with the scope or a differential amplifier, and mount the part in a PCB test jig replicating final layout to expose real coupling.

3.2 Test procedures & acceptance criteria

Point: Define repeatable procedures: zero-offset test, gain/linearity sweep 0→20 A, frequency sweep for bandwidth, step-pulse rise/fall, and temperature drift sweep. Evidence: Typical acceptance: gain within ±1% of nominal, offset within specified mV or mA-equivalent, bandwidth meeting −3 dB point near the datasheet value. Explanation: Log CSV columns: timestamp, commanded current, measured output (V), ambient temp, calculated current, error (%FS, %reading). Include plots: error vs current, Bode magnitude/phase, step response and noise histogram.

Test results: expected outcomes and how to analyze them

4.1 Accuracy, linearity and error breakdown

Point: Separate error into offset, gain, nonlinearity and temp drift. Evidence: Compute absolute error, %FS and %reading for each test point and visualize residuals and Bland–Altman style difference vs mean plots. Explanation: Residual plots will reveal slope error (gain) as a linear trend and offset as a constant bias; temperature sweeps can isolate thermal coefficients expressed in ppm/°C or mV/°C.

Recommended logging columns

timestamp, commanded current, measured output (V), ambient temp, calculated current, error (%FS, %reading)

Acceptance (example)

gain within ±1% reading; offset within ±5 mA-equivalent; −3 dB near datasheet bandwidth

4.2 Bandwidth, transient response and noise performance

Point: Present bandwidth via Bode plot, step tests for rise/fall times, and RMS/peak-to-peak noise for shorted-input conditions. Evidence: A −3 dB cutoff lower than datasheet suggests downstream filtering or higher-bandwidth device. Explanation: For PWM or fast transients, ensure rise time is short enough to capture pulses; if RMS noise approaches ADC LSBs, add low-pass filtering or increase ADC sampling averaging.

Illustrative magnitude response (sketch)

Low freq: flat

−3 dB ≈ 100 kHz

High freq: roll-off

Integration & application examples

5.1 PCB layout, filtering and decoupling recommendations

Point: Layout and decoupling strongly affect measured noise and offset. Evidence: Place the sensor away from high-current switching loops, route reference returns cleanly, and provide local decoupling on the sensor supply (e.g., 0.1 µF + 10 µF). Explanation: Use a single point ground for analog reference, add a small RC on the output (e.g., 1 kΩ + 100 nF) for anti-aliasing before ADC, and protect outputs with series resistors and TVS if exposed to transients.

5.2 Typical application circuits and scaling considerations

Point: The output is typically V/A; interface needs ADC scaling and potential offset compensation. Evidence: Example: if sensor outputs 50 mV/A, a 12-bit ADC with 3.3 V reference gives usable resolution—calculate conversion constants in firmware. Explanation: Implement firmware conversion: measured_V → measured_current = (measured_V - zero_offset_V) / sensitivity_V_per_A; add calibration routine to store offset and gain correction factors.

measured_current = (measured_V − zero_offset_V) / sensitivity_V_per_A

Purchasing, validation checklist & troubleshooting

6.1 Spec checklist before you buy

Point: Procurement must confirm a minimal set of datasheet fields. Evidence: At minimum verify nominal current, isolation rating and package footprint plus operating temp range. Explanation: Insist on datasheet pages for electrical characteristics, mechanical footprint PDF, and environmental ratings; obtain sample units and run the tests above prior to full production buy.

6.2 Common failure modes, diagnostics and fixes

Point: Frequent issues include offset shifts after soldering, noise coupling from switching traces, and saturation on overload. Evidence: Diagnostics: repeat zero test after reflow, inject controlled noise and observe coupling, apply overcurrent step to locate saturation point. Explanation: Mitigations include thermal reliefs on pads, improved shielding or trace rerouting, and adding series sense resistors or clamps to avoid saturation during faults.

Conclusion

Reading the L07P020D15 datasheet with a test-first mindset prevents surprises: verify offset, gain, bandwidth and isolation on a bench that mirrors the final PCB, adopt clear pass/fail tolerances, and follow layout and filtering best practices before deployment. The outlined tests and checks give a reproducible path from datasheet claims to validated system performance for any board-mount current sensor.

Key summary

Verify offset, gain and linearity across 0–20 A; use CSV logging of commanded current, measured voltage, derived current and error for traceable analysis.

Confirm bandwidth and rise time with frequency sweeps and pulse tests; if −3 dB is below needs, add signal conditioning or choose higher bandwidth sensor.

Design PCB with short sense traces, single-point analog ground, local decoupling and output filtering to minimize noise and offsets for ADC interfacing.

Frequently Asked Questions

How do I confirm the L07P020D15 zero offset after soldering?

Measure the output with conductor open-circuit (zero applied current) immediately after reflow and after thermal stabilization. Record offset in volts and convert to mA-equivalent using the sensor sensitivity; if offset shifts beyond acceptance (e.g., greater than specified mV or >5 mA-equivalent), investigate solder fillets and thermal stress.

What acceptance criteria should I use for current sensor linearity?

Use percent-of-reading and percent-of-full-scale metrics: for a 20 A nominal device, require gain within ±1% of reading across mid-range and nonlinearity under ±0.5% FS as a practical target for monitoring applications; tighten tolerances for precise metrology tasks.

When is additional filtering recommended for the current sensor output?

If measured RMS noise causes ADC quantization issues or if PWM switching injects high-frequency components beyond application bandwidth, add a small RC anti-alias filter (e.g., 1 kΩ and 100 nF) and consider digital averaging; ensure the filter corner does not impede required transient response.

(function(){

// Ensure accordion panels start collapsed on small screens while visible on desktop for readability.

try {

var acc = document.getElementById('faq-accordion');

if(!acc) return;

var buttons = acc.getElementsByTagName('button');

for(var i=0;i

READ MORE

MM74HC4050NSanyo Semiconductor/onsemiIC BUFFER NON-INVERT 6V 16DIP

MM74HC4050NSanyo Semiconductor/onsemiIC BUFFER NON-INVERT 6V 16DIP MM74HC4049NSanyo Semiconductor/onsemiIC BUFFER NON-INVERT 6V 16DIP

MM74HC4049NSanyo Semiconductor/onsemiIC BUFFER NON-INVERT 6V 16DIP MM74HC4040NSanyo Semiconductor/onsemiIC BINARY COUNTER 12-BIT 16DIP

MM74HC4040NSanyo Semiconductor/onsemiIC BINARY COUNTER 12-BIT 16DIP MM74HC4020NSanyo Semiconductor/onsemiIC BINARY COUNTER 14-BIT 16DIP

MM74HC4020NSanyo Semiconductor/onsemiIC BINARY COUNTER 14-BIT 16DIP MM74HC393NSanyo Semiconductor/onsemiIC BINARY COUNTR DL 4BIT 14MDIP

MM74HC393NSanyo Semiconductor/onsemiIC BINARY COUNTR DL 4BIT 14MDIP MM74HC374NSanyo Semiconductor/onsemiIC FF D-TYPE SNGL 8BIT 20DIP

MM74HC374NSanyo Semiconductor/onsemiIC FF D-TYPE SNGL 8BIT 20DIP MM74HC373NSanyo Semiconductor/onsemiIC D-TYPE TRANSP SGL 8:8 20DIP

MM74HC373NSanyo Semiconductor/onsemiIC D-TYPE TRANSP SGL 8:8 20DIP LT1213CS8Linear Technology (Analog Devices, Inc.)IC OPAMP GP 2 CIRCUIT 8SO

LT1213CS8Linear Technology (Analog Devices, Inc.)IC OPAMP GP 2 CIRCUIT 8SO MM74HC259NSanyo Semiconductor/onsemiIC LATCH ADDRESS 8BIT 16-DIP

MM74HC259NSanyo Semiconductor/onsemiIC LATCH ADDRESS 8BIT 16-DIP MM74HC251NSanyo Semiconductor/onsemiIC MULTIPLEXER 1 X 8:1 16DIP

MM74HC251NSanyo Semiconductor/onsemiIC MULTIPLEXER 1 X 8:1 16DIP