-

- Contact Us

2-5535512-2 Datasheet Deep Dive: Specs & Footprint

Introduction — Point: The 2-5535512-2 is a widely used PCB header whose presence in many distributor listings and manufacturer product pages signals the value of getting its mechanical and electrical details right early. Evidence: Boards that adopt the recommended footprint from the official product documentation typically avoid layout rework. Explanation: Use the 2-5535512-2 datasheet as the authoritative reference during PCB layout to reduce redesign cycles and improve first-pass yield.

Introduction — Point: A short statistic hook emphasizes impact. Evidence: Hundreds of assemblies reference this header in published BOMs, showing common engineering adoption. Explanation: Early datasheet review saves assembly time, reduces manufacturing scrap, and lowers NRE costs; treat the datasheet as the starting checklist for footprint, plating, termination, and mechanical anchors.

1 — Overview: What the 2-5535512-2 Datasheet Reveals

Key datasheet highlights to scan first

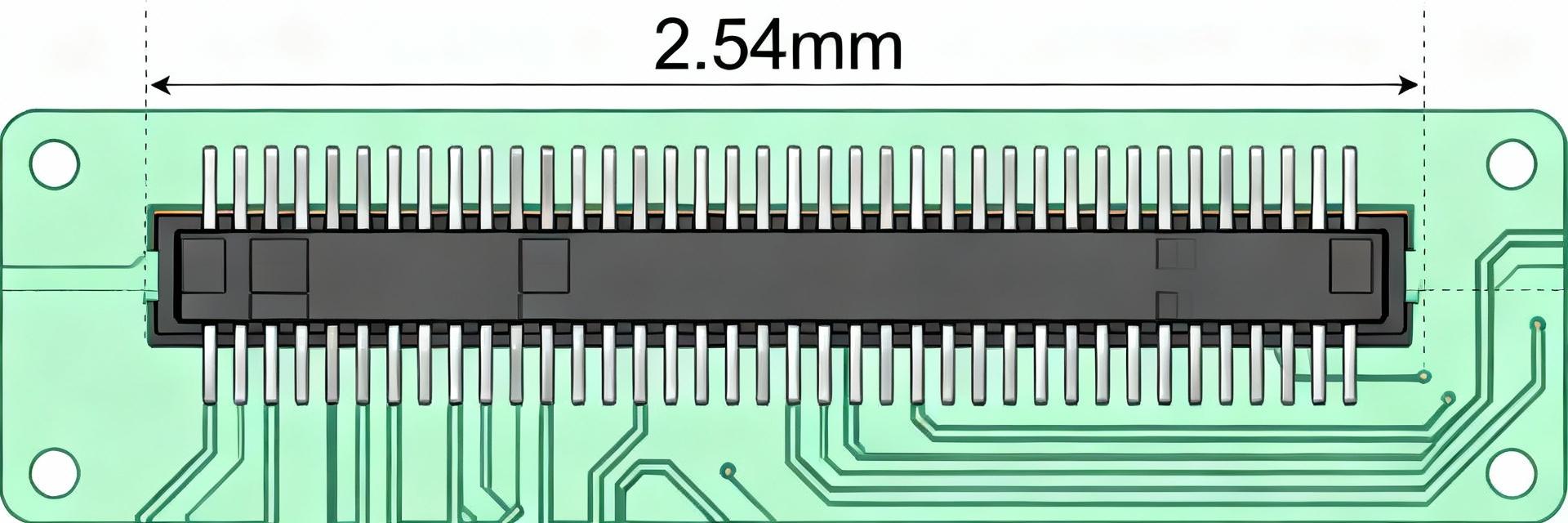

Point: Engineers first scan a one-page checklist before layout. Evidence: That checklist should confirm part family, pitch (2.54 mm / 0.100"), row/position count (30 positions typical), orientation (right-angle or straight), plating (gold over nickel typical), termination style (through-hole), and primary mechanical envelopes. Explanation: Verifying these items prevents mismatches between mating hardware and PCB land pattern; always consult the manufacturer's product page and PDF for the official tables before final Gerber output.

How to read part numbers and cross-references

Point: Part-number syntax encodes family and orientation. Evidence: Variants often differ by a leading digit or suffix indicating orientation or plating option; common variants simplify to the same mechanical family but differ in finish or packaging. Explanation: Cross-reference the exact ordering code versus the mechanical drawing to confirm mating compatibility; double-check distributor SKUs indirectly by comparing spec tables rather than relying on SKU text alone.

2 — Detailed Specs: Electrical, Mechanical & Material Data

Electrical specs to validate in design

Point: Validate contact resistance, current rating, insulation resistance, dielectric strength, and mating cycles. Evidence: Typical through-hole header contacts are rated for single-digit amperes per contact (design for derating), low milliohm contact resistance, high insulation resistance, and thousands of mating cycles. Explanation: Size adjacent PCB traces based on the per-contact current rating and apply safe derating rules; prioritize thermal management when routing multiple high-current pins in a group.

Mechanical & environmental specs

Point: Mechanical dimensions and materials determine footprint and reliability. Evidence: Key numbers to record: pitch 2.54 mm (0.100"), 30 positions, pin diameter and board-standoff (specified in the manufacturer table), phosphor bronze contacts with gold plating are common, and operating temperature ranges typically span wide industrial bounds. Explanation: Use the datasheet tables for exact pin diameter and standoff when creating drill and silkscreen rules; verify plating and temperature specs for high-reliability or harsh-environment products.

| Parameter | Typical Value |

|---|---|

| Pitch | 2.54 mm (0.100") |

| Positions | 30 |

| Orientation | Right-angle or straight (variant-dependent) |

| Contact plating | Gold over nickel (selective) |

| Termination | Through-hole |

3 — Footprint & PCB Layout Guide for 2-5535512-2

Recommended land pattern and drill sizes

Point: Follow an IPC-style land pattern and recommended drill sizes for reliable solder fillets and mechanical retention. Evidence: For a 2.54 mm pitch through-hole header, suggested pad centers are on a 2.54 mm grid with a plated-through hole sized to accommodate the pin diameter plus manufacturing clearance; typical drill suggestions fall in the 0.9–1.1 mm (0.035–0.043") range depending on pin thickness. Explanation: Define annular ring, solder mask clearance, and thermal relief for wave or selective soldering; include a footprint note that these dimensions are candidate values and must be confirmed against the official footprint table in the datasheet.

Placement, mechanical clearances & silkscreen rules

Point: Mechanical clearances and silkscreen practice avoid assembly issues. Evidence: Keep board edges and mounting fasteners clear of the connector mating area, and do not print silkscreen over pads. Explanation: Reserve a mating-keepout zone for cable/board mating, add plated-through anchor rows or glue points for high-stress environments, and mark connector orientation on silkscreen but offset to avoid mask slivers.

Gerber/IP C snippet (example land pattern notes): - Grid: 2.540 mm (0.100") centers - Hole Ø: 1.00 mm (0.039") nominal (verify pin Ø in datasheet) - Pad Ø: 2.30 mm (0.090") annular ring - Solder mask: 0.15 mm clearance - Thermal relief: per process standard

4 — Comparisons, Alternatives & Typical Use Cases

Close alternatives and cross-reference parts

Point: Alternatives vary by pitch, plating, and orientation. Evidence: Within the same family, variants differ only by plating or right-angle vs vertical execution; competing parts may change pitch or row count. Explanation: Select an alternative when your design constraints require different pitch, additional positions, or cost-driven plating changes; always compare mechanical drawings side by side to confirm hole pattern compatibility before substituting parts.

Typical applications and real-world examples

Point: Common uses include board-to-board headers, mezzanine connectors, and module interfaces. Evidence: This header is often chosen for controllers, prototyping rigs, and compact module stacking where a robust through-hole anchor and reliable signal path are needed. Explanation: For consumer devices prioritize minimal profile; for industrial controllers emphasize plating and mechanical anchoring for vibration resistance.

5 — Design-to-Manufacturing Checklist & Validation Tests

Assembly, soldering and handling recommendations

Point: Solder process selection drives yield. Evidence: Through-hole headers accept wave, selective, or hand soldering; recommended solder alloys and temperature profiles should be aligned with the plating system. Explanation: Define the soldering profile consistent with the header's finish—avoid excessive dwell that can leach plating—and implement fixturing for right-angle parts to prevent tombstoning during reflow or selective solder operations.

Inspection & validation tests to run before production

Point: Pre-production tests catch mechanical and electrical issues early. Evidence: Run DFM checks, IPC footprint verification, continuity/contact resistance tests, mechanical pull/torque tests, and environmental stress (thermal cycling, vibration). Explanation: Create a short pre-production checklist for PCB fab and assembly: IPC footprint pass, drilled-hole verification, solderability test, and a sample mechanical retention test to validate anchors under expected service loads.

Key Summary

- Use the official 2-5535512-2 datasheet as the authoritative reference for pitch, plating, and termination to avoid layout rework and ensure first-pass yield.

- Verify electrical specs (current rating, contact resistance) and derate traces; route high-current pins with thermal relief and appropriate trace width.

- Create an IPC-style land pattern: 2.54 mm grid, confirm hole Ø from the datasheet, set solder mask clearance and annular ring per fab capability.

- Plan mechanical keep-outs, standoffs, and silkscreen off-pad markings; fixture right-angle through-hole parts during assembly to prevent alignment issues.

- Run DFM, continuity, and mechanical retention tests pre-production to catch issues before a full production run.

Frequently Asked Questions

What is the recommended drill size for the 2-5535512-2 footprint?

Answer: Drill size depends on the pin diameter specified in the official drawing; a typical through-hole header of this pitch often uses a nominal 1.0 mm (0.039") drill, with exact clearance set by your fabricator’s plating tolerance. Always verify the pin Ø listed in the datasheet and add the manufacturer-recommended clearance before finalizing NC drill files.

How should I size PCB traces near the 2-5535512-2 for current carrying?

Answer: Use the per-contact current rating from the datasheet and apply standard PCB trace-width calculators with a conservative derating factor. For multiple adjacent high-current pins, route traces with increased copper weight or parallel runs, and ensure thermal relief for wave soldering if required.

Are there special soldering profiles for the 2-5535512-2 solder joints?

Answer: Soldering profile choice (wave, selective, hand) should match the header plating and the overall assembly process. Follow standard through-hole soldering recommendations: controlled preheat, appropriate peak temperature for the solder alloy in use, and limited dwell to protect gold plating; consult your assembler and the manufacturer’s notes for the recommended profile.

Can I substitute a similar part with a different suffix or variant?

Answer: Substitutions are possible within the same mechanical family if the hole pattern, pitch, and standoff match exactly. Confirm mating compatibility and plating differences by comparing mechanical drawings and finish notes; do not rely solely on SKU text—use dimensional tables to validate interchangeability.

What pre-production checks should I run for board acceptance?

Answer: Run an IPC footprint check, verify NC drill outputs, perform continuity and contact resistance measurements on a populated sample, and execute a mechanical pull/torque test. Add a small pilot run with full assembly to validate solderability and mechanical retention under expected handling and environmental conditions.

Summary — Point: Referencing the official 2-5535512-2 datasheet early prevents costly rework. Evidence: Following the recommended footprint, layout, and validation steps reduces scrap and improves first-pass yield. Explanation: Use the checklist, land pattern guidance, and pre-production tests above to validate designs before committing to full production.

- Technical Features of PMIC DC-DC Switching Regulator TPS54202DDCR

- STM32F030K6T6: A High-Performance Core Component for Embedded Systems

- Tamura L34S1T2D15 Datasheet Breakdown: Key Specs & Limits

- PAL6055.700HLT Datasheet: Complete Technical Report

- FDP027N08B MOSFET Datasheet Deep-Dive: Key Specs & Test Data

- LT1074IT7: Complete Specs & Key Parameters Breakdown

- How to Verify G88MP061028 Datasheet and Specs - Checklist

- NFAQ0860L36T Datasheet: Measured IPM Performance Report

- 90T03P MOSFET: Complete Specs, Pinout & Ratings Digest

- 3386F-1-101LF Datasheet & Specs — Pinout, Ratings, Sources

-

MM74HC4050NSanyo Semiconductor/onsemiIC BUFFER NON-INVERT 6V 16DIP

MM74HC4050NSanyo Semiconductor/onsemiIC BUFFER NON-INVERT 6V 16DIP -

MM74HC4049NSanyo Semiconductor/onsemiIC BUFFER NON-INVERT 6V 16DIP

MM74HC4049NSanyo Semiconductor/onsemiIC BUFFER NON-INVERT 6V 16DIP -

MM74HC4040NSanyo Semiconductor/onsemiIC BINARY COUNTER 12-BIT 16DIP

MM74HC4040NSanyo Semiconductor/onsemiIC BINARY COUNTER 12-BIT 16DIP -

MM74HC4020NSanyo Semiconductor/onsemiIC BINARY COUNTER 14-BIT 16DIP

MM74HC4020NSanyo Semiconductor/onsemiIC BINARY COUNTER 14-BIT 16DIP -

MM74HC393NSanyo Semiconductor/onsemiIC BINARY COUNTR DL 4BIT 14MDIP

MM74HC393NSanyo Semiconductor/onsemiIC BINARY COUNTR DL 4BIT 14MDIP -

MM74HC374NSanyo Semiconductor/onsemiIC FF D-TYPE SNGL 8BIT 20DIP

MM74HC374NSanyo Semiconductor/onsemiIC FF D-TYPE SNGL 8BIT 20DIP -

MM74HC373NSanyo Semiconductor/onsemiIC D-TYPE TRANSP SGL 8:8 20DIP

MM74HC373NSanyo Semiconductor/onsemiIC D-TYPE TRANSP SGL 8:8 20DIP -

LT1213CS8Linear Technology (Analog Devices, Inc.)IC OPAMP GP 2 CIRCUIT 8SO

LT1213CS8Linear Technology (Analog Devices, Inc.)IC OPAMP GP 2 CIRCUIT 8SO -

MM74HC259NSanyo Semiconductor/onsemiIC LATCH ADDRESS 8BIT 16-DIP

MM74HC259NSanyo Semiconductor/onsemiIC LATCH ADDRESS 8BIT 16-DIP -

MM74HC251NSanyo Semiconductor/onsemiIC MULTIPLEXER 1 X 8:1 16DIP

MM74HC251NSanyo Semiconductor/onsemiIC MULTIPLEXER 1 X 8:1 16DIP