-

- Contact Us

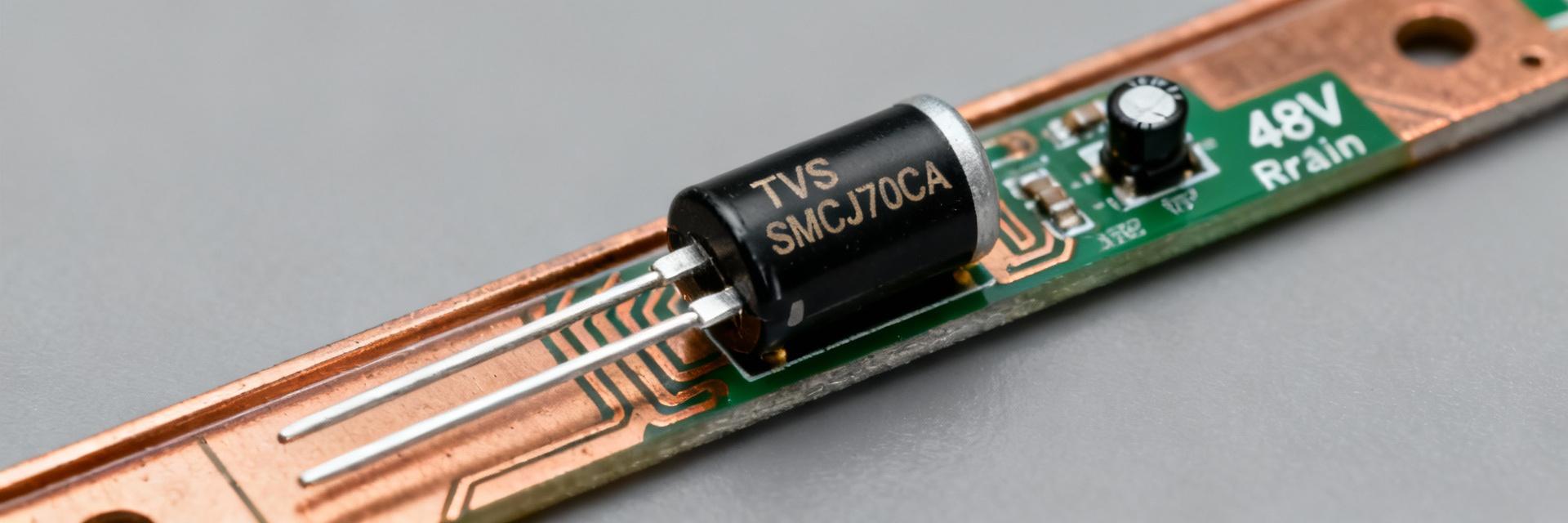

SMCJ70CA TVS Diode: Complete Electrical Datasheet & Specs

The SMCJ70CA is rated for 1.5 kW peak pulse power (10/1000 μs) and clamps at ~113 V at a 13.3 A 10/1000 μs pulse — making it a go‑to TVS diode for high‑energy transient suppression. This article breaks down the SMCJ70CA electrical datasheet, explains how to verify the key ratings in the lab, and gives practical design and sourcing guidance for design engineers, procurement, and test engineers working on telecom, industrial 48 V, and I/O protection systems. It covers static and dynamic characteristics, thermal limits, test waveforms, and actionable checklists to qualify parts for production.

1 — At‑a‑Glance: What the SMCJ70CA Is (Background)

Point: The SMCJ70CA is a high‑energy transient voltage suppressor in an SMB (DO‑214AB) package intended for surge and ESD protection on higher‑voltage rails. Evidence: Manufacturers publish the part as available in unidirectional and bidirectional variants with standard SMB footprints and manufacturer marking codes for cross‑reference. Explanation: For boards requiring robust surge handling without large external surge components, the SMCJ70CA’s 1.5 kW PPPM rating (10/1000 μs) and the SMB form factor offer a compact, board‑level solution compatible with automated pick‑and‑place and standard reflow processes.

H3: Part identity and package

Point: The SMCJ70CA appears across multiple suppliers (Littelfuse, Bourns, Eaton, Fairchild) and is offered as both unidirectional and bidirectional devices in the DO‑214AB (SMB) package. Evidence: Typical marking codes and package outlines are shown on vendor datasheets; cross‑refs use the same electrical family name SMCJ. Explanation: Unidirectional parts are recommended for DC rails where reverse polarity is not expected; bidirectional parts are chosen for AC or bidirectional I/O lines. Verify package dimensions and solder pad recommendations in the supplier datasheet before footprint finalization.

H3: Key electrical ratings overview (quick spec table)

Point: Quick reference specs speed decisions during design reviews. Evidence: Core values to capture are VRWM = 70 V, Vbr (breakdown) range per datasheet, Ipp = 13.3 A @10/1000 μs, PPPM = 1500 W (10/1000 μs), Vclamp ≈ 113 V at the stated pulse, reverse leakage at VRWM, and recommended Tj operating range. Explanation: These figures determine whether the part meets system margin and thermal limits — use them for initial selection before deep verification.

| Parameter | Typical / Value |

|---|---|

| VRWM | 70 V |

| Breakdown Vbr (min/typ) | ~81.9 V (datasheet ranges) |

| Ipp (10/1000 μs) | 13.3 A |

| Peak Pulse Power (10/1000 μs) | 1500 W |

| Vclamp @ Ipp | ~113 V |

| Reverse leakage (IR) | μA to mA range at VRWM (temp dependent) |

| Operating junction | typ. −55 °C to +150 °C |

H3: Typical applications at a glance

Point: The SMCJ70CA is used for high‑energy suppression on telecom power rails, industrial 48 V systems, I/O ESD protection, and some automotive auxiliary lines. Evidence: The VRWM and PPPM ratings align with common surge profiles in telecom power feeds and industrial DC distribution where 48 V nominal rails are present. Explanation: For telecom and industrial use, the combination of high PPPM and manageable clamp voltage protects downstream converters and loads; for I/O protection, the device is placed at board edges with series resistance or filtering to tame ESD and EFT events. In automotive applications limited to non‑ISO auxiliary lines, ensure transient profiles and temperature extremes are within the part’s derating curves.

2 — Datasheet Deep‑Dive: Electrical Characteristics Explained (Data analysis)

Point: The datasheet’s electrical sections translate to selection criteria: static/DC specs set bias behavior; dynamic specs define transient handling; thermal limits set operational boundaries. Evidence: Datasheet tables contain VRWM, Vbr(min/typ), IR, clamping curves, PPPM, and thermal resistance values. Explanation: Understanding how each parameter is measured and how it varies with temperature and pulse width is essential to predict real‑world performance and to avoid misinterpreting vendor numbers.

H3: Static / DC characteristics

Point: VRWM (Reverse Stand‑Off Voltage) and Vbr define when the device begins to conduct in reverse; IR indicates leakage at VRWM and grows with temperature. Evidence: Datasheet entries show VRWM = 70 V and a Vbr range with min/typ values; reverse leakage is often specified at 25 °C and at higher temps. Explanation: Select VRWM at or above the highest steady‑state system voltage plus design margin (typically 10–20%). Account for leakage when choosing parts for low‑power rails — elevated IR at high temperature can increase standby loss or create false triggers for undervoltage detection circuits.

H3: Pulse and transient ratings (dynamic)

Point: Peak pulse current (Ipp), peak pulse power (PPPM), and clamping voltage vs. current curves define transient response. Evidence: The PPPM value (1500 W @10/1000 μs) and Ipp (13.3 A @10/1000 μs) paired with Vclamp ≈ 113 V at that Ipp are typical datasheet entries. Explanation: Use the clamping curve to estimate voltage seen by protected circuits during a surge. Note waveform dependence: 10/1000 μs specifies energy‑heavy surge (telecom style), while 8/20 μs represents lightning/IEC surge — the device will exhibit different Ipp and Vclamp values for each waveform. Choose the waveform that matches your system’s threat model or request vendor test data for the specific waveform of concern.

H3: Thermal & mechanical limits

Point: Maximum junction temperature, solder/reflow limits, and thermal resistance govern derating and reliability. Evidence: Datasheets list Tj operating range and solder recommendations; some include junction‑to‑ambient or junction‑to‑lead thermal resistance. Explanation: High energy pulses produce localized heating — repeated surges or inadequate copper area can raise junction temperature and lead to thermal runaway. Follow recommended solder profiles and use copper pours/thermal vias to lower RθJA. Apply derating rules based on expected surge repetition and ambient conditions to avoid cumulative damage.

3 — How to Read, Verify and Test the Values in the Datasheet (Method / Practical guide)

Point: Knowing the test waveforms, measurement setups, and graph interpretation methods enables accurate verification of datasheet claims. Evidence: Standards such as IEC 61000‑4‑2 and surge waveform definitions (10/1000 μs, 8/20 μs) are referenced by suppliers. Explanation: Request vendor test reports that specify waveform, pulse energy, and measurement clamps; in the lab, reproduce the waveform and document test rig impedance, probe placement, and environmental conditions to ensure repeatable results.

H3: Test waveforms and standards to know

Point: Common waveforms are 10/1000 μs (battery/telecom surge), 8/20 μs (lightning/surge), and ESD per IEC 61000‑4‑2. Evidence: Supplier datasheets often list PPPM by 10/1000 μs and provide clamping curves under specified test currents. Explanation: When specifying tests in procurement, include waveform type, pulse energy, repetition rate, and measurement bandwidth. For ESD, request IEC 61000‑4‑2 contact and air discharge levels with device placement defined.

H3: Practical lab measurements (clamp voltage, leakage)

Point: Measure Vclamp with a calibrated surge generator, low‑inductance connections, and a high‑bandwidth voltage probe; measure leakage with a source meter at controlled temperature. Evidence: Typical lab setups use low‑impedance coax, Kelvin connections, and clamps to avoid stray inductance that artificially increases Vclamp. Explanation: To obtain meaningful Vclamp data, minimize loop inductance between generator, DUT, and measurement point; capture both peak and tail of the waveform. For IR, stabilize temperature and measure after thermal equilibrium — leakage doubles or more per ~10 °C in many junctions.

H3: Interpreting graphs and derating curves

Point: Energy vs. pulse width and temperature derating charts let you map real threat pulses to allowable surge counts and power. Evidence: Datasheets show energy handling curves and sometimes pulse repetition limits. Explanation: Map your system’s transient profile (amplitude and duration) onto the energy vs. pulse width chart to verify the device won’t exceed rated energy. Apply temperature derating to account for elevated ambient and internal heating during repeated events.

4 — Design & Application Examples (Case studies)

Point: Practical cases illustrate selection, layout, and expected behavior. Evidence: Using the SMCJ70CA on a 48 V rail or at an I/O edge demonstrates layout and series component choices. Explanation: Walkthroughs below give stepwise margin calculations, layout tips, and thermal strategies to meet PPPM requirements while minimizing clamp voltage impact on sensitive circuitry.

H3: Example 1 — Protecting a 48 V industrial power rail

Point: For a 48 V nominal bus, choose VRWM above steady‑state plus margin and ensure clamp limits protect downstream converters. Evidence: With VRWM = 70 V, SMCJ70CA leaves margin above 48 V and clamps near 113 V at a full pulse. Explanation: Calculate margin: 48 V steady + transients (e.g., 10–20%) → choose VRWM ≥ 55 V; SMCJ70CA’s 70 V VRWM provides conservative margin. Layout: place device close to feed input, provide large copper for heat sinking, and consider a series surge resistor if clamp voltage must be reduced during extreme events.

H3: Example 2 — ESD protection for serial / I/O interfaces

Point: At board edges, use SMCJ70CA (uni or bi) combined with series resistance and RC filtering to handle EFT/ESD bursts. Evidence: Clamping behavior at IEC‑level ESD shows high slope in Vclamp vs. I curves; series elements limit current into the TVS. Explanation: For high‑speed I/O, add small series resistors or ferrites to limit current into the TVS and avoid signal integrity issues. Place the TVS at the first point of contact, minimize trace inductance, and verify behavior with IEC 61000‑4‑2 test pulses.

H3: PCB layout and thermal management case study

Point: Copper area, vias, and proximity to protected line determine thermal performance during surges. Evidence: RθJA decreases with larger copper pads and thermal vias; placement close to entry reduces loop inductance and improves clamping. Explanation: Use wide traces, a dedicated copper pour under the SMB pad, and multiple thermal vias to an inner or bottom plane. Keep traces between the protected node and TVS short and straight to reduce stray inductance and thus lower transient overshoot.

5 — Selection, Sourcing, Substitution & Qualification Checklist (Actionable)

Point: A structured checklist avoids common procurement and qualification mistakes. Evidence: Cross‑supplier differences in test waveforms, marking, and tested limits require verification against procurement specs. Explanation: Follow the checklist below to ensure the selected device meets system needs and is verifiable in production testing.

H3: Selection checklist (unidirectional vs bidirectional, margin, surge count)

Point: Follow stepwise selection: identify transient energy and waveform, choose VRWM with margin, confirm clamp at Ipp, verify PPPM and repetition tolerance. Evidence: Datasheet entries for VRWM, Vclamp, PPPM, and pulse repetition guidance inform each step. Explanation: Document expected threat levels, required margin, and acceptable clamp voltage; require vendor confirmation of waveform tested and provide sample parts for lab verification.

H3: Cross‑references and sourcing (Littelfuse, Bourns, Eaton, Fairchild)

Point: Cross‑reference common equivalent part numbers but verify marking, package and tested waveforms in each manufacturer’s datasheet. Evidence: Several vendors publish SMCJ series datasheets with slight differences in Vbr ranges and test conditions; the descriptive family name SMCJ70CA is commonly used. Explanation: When substituting, confirm the datasheet‑listed Vclamp at the same Ipp and the same waveform (10/1000 μs vs 8/20 μs). For traceability and procurement, require manufacturer lot data and test condition certificates. Note also that SMCJ70CA‑HCA1 is used as an internal or distributor SKU in some catalogs — confirm that this SKU maps exactly to the intended manufacturer part.

H3: Qualification & field testing steps before production

Point: Define sample sizes, required tests, and acceptance criteria in procurement documents. Evidence: Recommended tests include Vclamp at specified Ipp/waveform, IR at multiple temperatures, ESD per IEC 61000‑4‑2, and surge endurance at intended repetition rates. Explanation: Include lot traceability, require test reports showing waveform and measurement bandwidth, and perform accelerated stress tests (temperature cycling, surge repetition) on production lots. Maintain a qualification report with pass/fail criteria tied to the datasheet numbers.

Summary

- The SMCJ70CA is a robust 1.5 kW (10/1000 μs) TVS diode solution that clamps around 113 V at 13.3 A, suitable for telecom and 48 V industrial rails and I/O protection when properly derated and laid out.

- Reading the datasheet requires attention to waveform definitions (10/1000 μs vs 8/20 μs), VRWM vs Vbr, and temperature dependence of leakage and clamp behavior to predict in‑system performance.

- Lab verification (surge generator for Vclamp, source meter for IR) with low‑inductance setups is essential to confirm vendor claims and to qualify the part for production use.

- A procurement checklist and cross‑reference verification (including confirming datasheet waveform and marking) prevent mismatches; note distributor SKUs such as SMCJ70CA‑HCA1 in purchasing records.

— Frequently Asked Questions

H3: What is the typical clamp voltage of the SMCJ70CA and how is it measured?

Clamp voltage for the SMCJ70CA is typically around 113 V at the datasheet Ipp of 13.3 A using a 10/1000 μs surge. Measurement uses a calibrated surge generator, low‑inductance connections, and a high‑bandwidth voltage probe placed directly across the device. The measured Vclamp varies with waveform, source impedance, measurement loop inductance, and temperature — so specify the exact test waveform and setup when comparing vendor numbers.

H3: How do I choose between unidirectional and bidirectional SMCJ70CA variants?

Choose unidirectional if the protected circuit is DC and reverse‑polarity protection is not required, since uni parts present lower forward conduction in the non‑clamped direction. Select bidirectional for AC or bidirectional I/O lines. Also consider clamping asymmetry, leakage, and the system’s maximum steady‑state voltage; ensure VRWM selection provides sufficient margin for the intended load.

H3: How many surge events can the SMCJ70CA tolerate in the field?

Manufacturer PPPM and pulse repetition guidance define allowable single‑pulse energy, but total surge count tolerance depends on pulse energy, repetition rate, and thermal environment. Qualification tests should include repeated pulses at the worst‑case energy and ambient to observe any drift in Vclamp or leakage. Define acceptance criteria in procurement and run accelerated surge endurance tests to estimate field lifetime under expected surge rates.

- Technical Features of PMIC DC-DC Switching Regulator TPS54202DDCR

- STM32F030K6T6: A High-Performance Core Component for Embedded Systems

- Tamura L34S1T2D15 Datasheet Breakdown: Key Specs & Limits

- PAL6055.700HLT Datasheet: Complete Technical Report

- FDP027N08B MOSFET Datasheet Deep-Dive: Key Specs & Test Data

- LT1074IT7: Complete Specs & Key Parameters Breakdown

- How to Verify G88MP061028 Datasheet and Specs - Checklist

- NFAQ0860L36T Datasheet: Measured IPM Performance Report

- 90T03P MOSFET: Complete Specs, Pinout & Ratings Digest

- 3386F-1-101LF Datasheet & Specs — Pinout, Ratings, Sources

-

MM74HC4050NSanyo Semiconductor/onsemiIC BUFFER NON-INVERT 6V 16DIP

MM74HC4050NSanyo Semiconductor/onsemiIC BUFFER NON-INVERT 6V 16DIP -

MM74HC4049NSanyo Semiconductor/onsemiIC BUFFER NON-INVERT 6V 16DIP

MM74HC4049NSanyo Semiconductor/onsemiIC BUFFER NON-INVERT 6V 16DIP -

MM74HC4040NSanyo Semiconductor/onsemiIC BINARY COUNTER 12-BIT 16DIP

MM74HC4040NSanyo Semiconductor/onsemiIC BINARY COUNTER 12-BIT 16DIP -

MM74HC4020NSanyo Semiconductor/onsemiIC BINARY COUNTER 14-BIT 16DIP

MM74HC4020NSanyo Semiconductor/onsemiIC BINARY COUNTER 14-BIT 16DIP -

MM74HC393NSanyo Semiconductor/onsemiIC BINARY COUNTR DL 4BIT 14MDIP

MM74HC393NSanyo Semiconductor/onsemiIC BINARY COUNTR DL 4BIT 14MDIP -

MM74HC374NSanyo Semiconductor/onsemiIC FF D-TYPE SNGL 8BIT 20DIP

MM74HC374NSanyo Semiconductor/onsemiIC FF D-TYPE SNGL 8BIT 20DIP -

MM74HC373NSanyo Semiconductor/onsemiIC D-TYPE TRANSP SGL 8:8 20DIP

MM74HC373NSanyo Semiconductor/onsemiIC D-TYPE TRANSP SGL 8:8 20DIP -

LT1213CS8Linear Technology (Analog Devices, Inc.)IC OPAMP GP 2 CIRCUIT 8SO

LT1213CS8Linear Technology (Analog Devices, Inc.)IC OPAMP GP 2 CIRCUIT 8SO -

MM74HC259NSanyo Semiconductor/onsemiIC LATCH ADDRESS 8BIT 16-DIP

MM74HC259NSanyo Semiconductor/onsemiIC LATCH ADDRESS 8BIT 16-DIP -

MM74HC251NSanyo Semiconductor/onsemiIC MULTIPLEXER 1 X 8:1 16DIP

MM74HC251NSanyo Semiconductor/onsemiIC MULTIPLEXER 1 X 8:1 16DIP