-

- Contact Us

YACT20JE06PNC00100A datasheet: pinout, specs & sourcing

Interest in the YACT20JE06PNC00100A datasheet has risen as engineering teams evaluate replacements and board-level integration options. This guide summarizes the part identity, concise pinout, electrical and mechanical highlights, practical integration tips, and a procurement checklist so engineers can rapidly assess fit-for-purpose without hunting through multiple distributor listings.

Overview: YACT20JE06PNC00100A Datasheet at a Glance

Part Identity & Typical Applications

The device is a compact semiconductor intended for board-level power/signal management and interface functions. It typically appears in mid-power rails, supervisory circuits, or as an interface translate block. Engineers scanning a BOM will treat it as a small-package, single-function IC—useful in power distribution, rail sequencing, or signal conditioning. It is a small-package interface/power component optimized for compact PCBs and constrained thermal environments.

Visual Performance Metrics

Quick-Spec Summary

| Spec | Typical Value / Range |

|---|---|

| Supply voltage (Vcc) | 1.8–5.5 V |

| Max continuous current | Up to 2 A (package dependent) |

| Package | Small SMT package (e.g., 8-pin DFN/SOP equivalent) |

| Temp range | -40°C to +85°C (commercial) / extended options possible |

| Key ratings | ESD protection, thermal limit, absolute max Vcc |

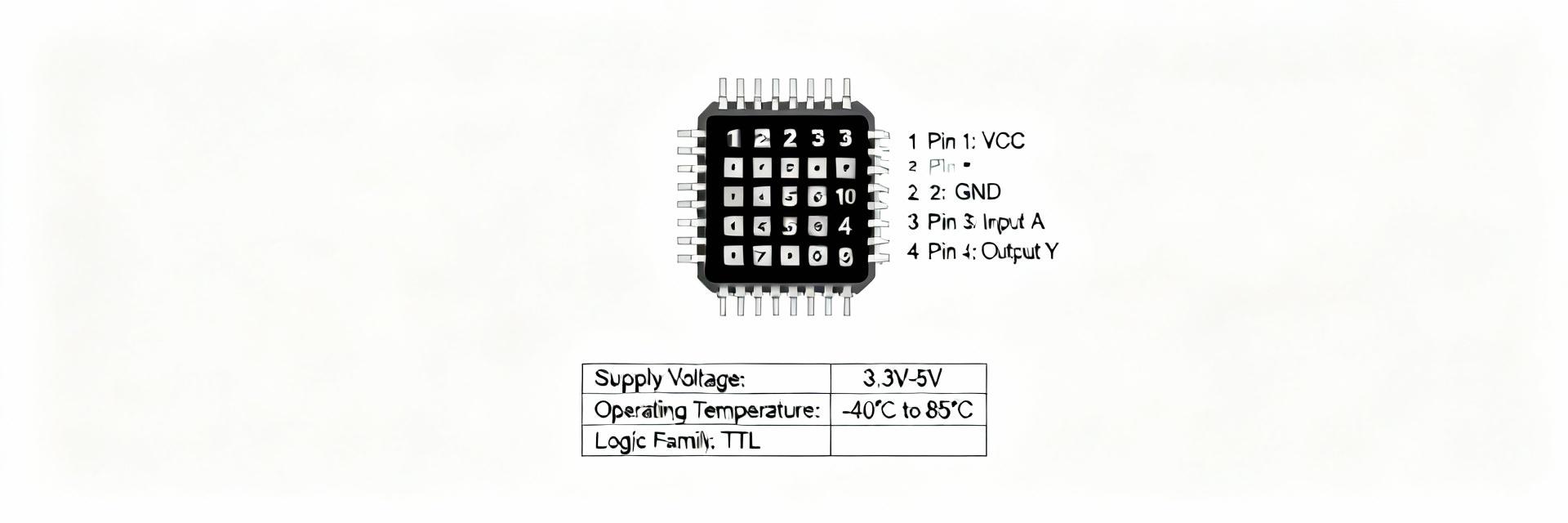

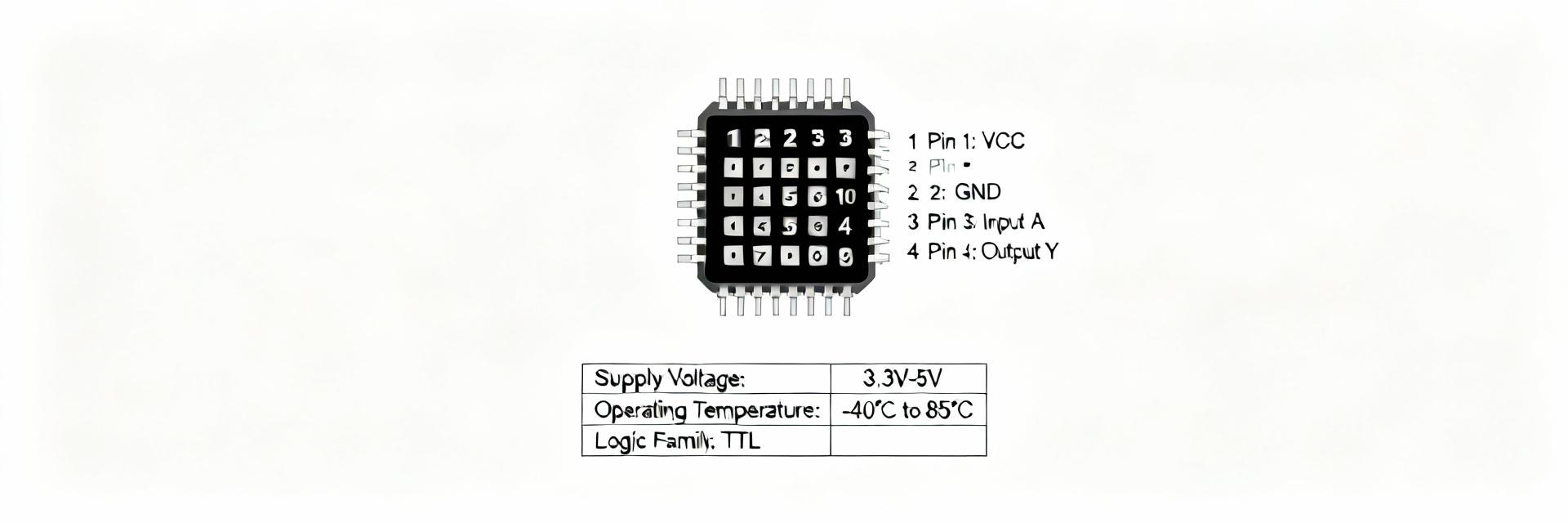

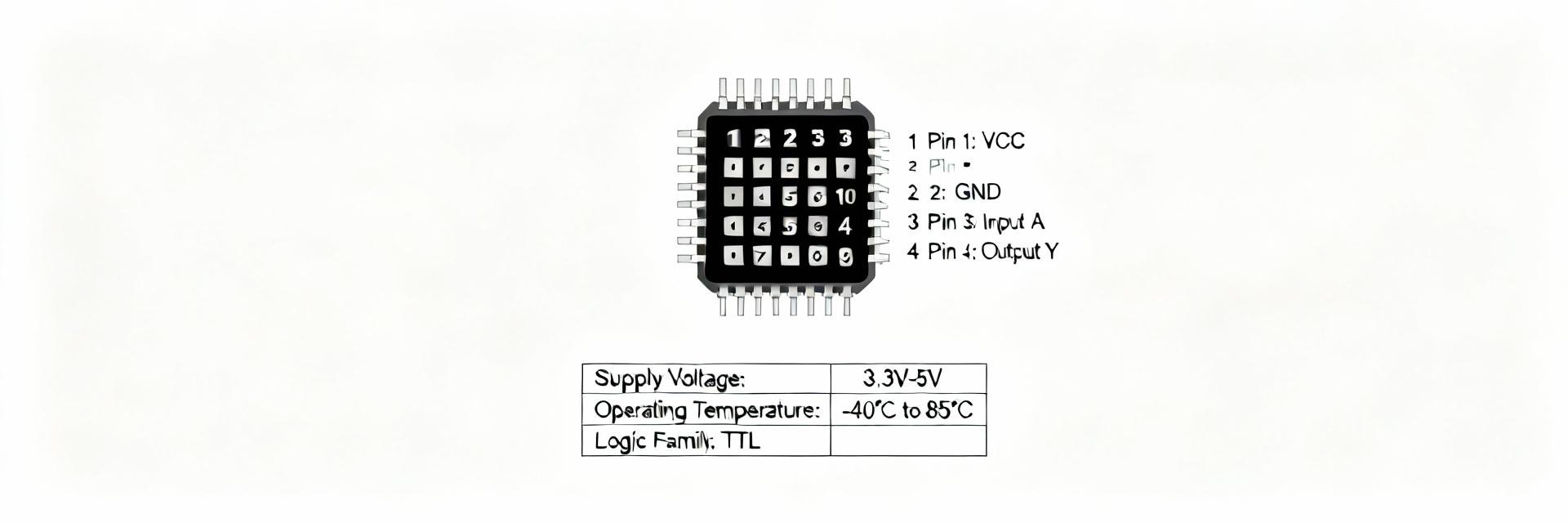

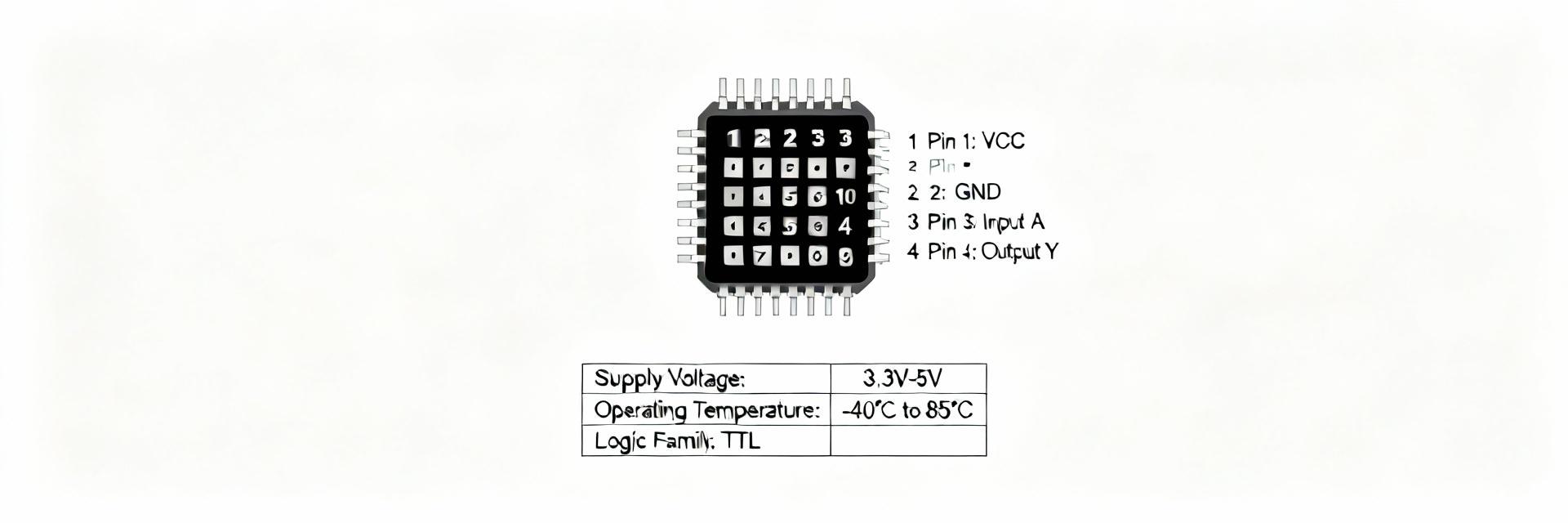

Pinout & Electrical Characteristics

A clear pinout table reduces probe time and miswiring risk. Below is a compact example map engineers can adapt to board silkscreen or schematic symbols using consistent naming conventions (VCC, GND, IN, OUT, EN, NC).

| Pin | Name | Type | Function |

|---|---|---|---|

| 1 | VCC | Power | Primary supply input, decouple close to pin |

| 2 | GND | Power | Return, connect to star ground |

| 3 | EN | I/O | Enable input, logic-high enable |

| 4 | IN | Input | Signal or sense input |

| 5 | OUT | Output | Output driver or switched rail |

| 6 | NC | - | No connect / mechanical support |

| 7 | TEST | I/O | Factory/test pin — avoid driving in production |

| 8 | PAD | Thermal | Exposed pad for thermal dissipation |

Note: include the pinout on the schematic sheet and a labeled PCB silk to speed validation and debug.

Mechanical, Package & Environmental Specs

Package Dimensions & Layout

Accurate mechanical drawings prevent footprint errors. Provide recommended land pattern dimensions with precise tolerances, pad-to-pad spacing, and exposed pad size for thermal relief. Include solder mask clearance and fillet notes; for small DFN-like packages, expose the thermal pad, provide teardrops on thermal vias, and keep decoupling caps within 1–2 mm. Use metric units on US boards when collaborating internationally.

Environmental & Reliability

Reliability and environmental ratings inform qualification effort. Summarize operating/storage temperature ranges, recommended MSL (if supplied), and theta_JA / theta_JC thermal resistance. Flag parts with tight thermal limits or low MSL ratings that require careful handling; if theta_JA is high, plan for copper pours or thermal vias to meet power dissipation requirements.

Integration & Implementation Guide

- Technical Features of PMIC DC-DC Switching Regulator TPS54202DDCR

- STM32F030K6T6: A High-Performance Core Component for Embedded Systems

- Tamura L34S1T2D15 Datasheet Breakdown: Key Specs & Limits

- PAL6055.700HLT Datasheet: Complete Technical Report

- FDP027N08B MOSFET Datasheet Deep-Dive: Key Specs & Test Data

- LT1074IT7: Complete Specs & Key Parameters Breakdown

- How to Verify G88MP061028 Datasheet and Specs - Checklist

- NFAQ0860L36T Datasheet: Measured IPM Performance Report

- 90T03P MOSFET: Complete Specs, Pinout & Ratings Digest

- 3386F-1-101LF Datasheet & Specs — Pinout, Ratings, Sources

-

MM74HC4050NSanyo Semiconductor/onsemiIC BUFFER NON-INVERT 6V 16DIP

MM74HC4050NSanyo Semiconductor/onsemiIC BUFFER NON-INVERT 6V 16DIP -

MM74HC4049NSanyo Semiconductor/onsemiIC BUFFER NON-INVERT 6V 16DIP

MM74HC4049NSanyo Semiconductor/onsemiIC BUFFER NON-INVERT 6V 16DIP -

MM74HC4040NSanyo Semiconductor/onsemiIC BINARY COUNTER 12-BIT 16DIP

MM74HC4040NSanyo Semiconductor/onsemiIC BINARY COUNTER 12-BIT 16DIP -

MM74HC4020NSanyo Semiconductor/onsemiIC BINARY COUNTER 14-BIT 16DIP

MM74HC4020NSanyo Semiconductor/onsemiIC BINARY COUNTER 14-BIT 16DIP -

MM74HC393NSanyo Semiconductor/onsemiIC BINARY COUNTR DL 4BIT 14MDIP

MM74HC393NSanyo Semiconductor/onsemiIC BINARY COUNTR DL 4BIT 14MDIP -

MM74HC374NSanyo Semiconductor/onsemiIC FF D-TYPE SNGL 8BIT 20DIP

MM74HC374NSanyo Semiconductor/onsemiIC FF D-TYPE SNGL 8BIT 20DIP -

MM74HC373NSanyo Semiconductor/onsemiIC D-TYPE TRANSP SGL 8:8 20DIP

MM74HC373NSanyo Semiconductor/onsemiIC D-TYPE TRANSP SGL 8:8 20DIP -

LT1213CS8Linear Technology (Analog Devices, Inc.)IC OPAMP GP 2 CIRCUIT 8SO

LT1213CS8Linear Technology (Analog Devices, Inc.)IC OPAMP GP 2 CIRCUIT 8SO -

MM74HC259NSanyo Semiconductor/onsemiIC LATCH ADDRESS 8BIT 16-DIP

MM74HC259NSanyo Semiconductor/onsemiIC LATCH ADDRESS 8BIT 16-DIP -

MM74HC251NSanyo Semiconductor/onsemiIC MULTIPLEXER 1 X 8:1 16DIP

MM74HC251NSanyo Semiconductor/onsemiIC MULTIPLEXER 1 X 8:1 16DIP