What are the product standards for integrated circuit development?

What are the Product Standards for Integrated Circuit Development?

I. Introduction

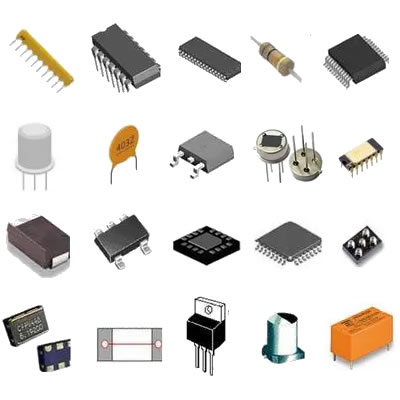

Integrated Circuits (ICs) are the backbone of modern electronics, enabling the functionality of everything from smartphones to sophisticated computing systems. These tiny chips, which can contain millions of transistors, are essential for processing, storing, and transmitting data. As the demand for more powerful and efficient ICs continues to grow, so does the importance of adhering to product standards in their development. Product standards ensure that ICs meet specific criteria for performance, reliability, and safety, ultimately leading to better products and enhanced consumer trust. This blog post will explore the historical context of IC standards, key product standards, compliance processes, challenges faced in meeting these standards, and future trends in IC development.

II. Historical Context of IC Standards

The journey of integrated circuits began in the late 1950s, with the invention of the first IC by Jack Kilby and Robert Noyce. As the technology evolved, so did the need for standards to ensure compatibility and reliability. Early standards were often informal and developed within specific companies or research institutions. However, as the industry grew, the need for a more structured approach became evident.

Industry organizations played a crucial role in establishing these standards. Groups like the Institute of Electrical and Electronics Engineers (IEEE) and the International Electrotechnical Commission (IEC) began to formalize standards that would govern the design, testing, and manufacturing of ICs. These early efforts laid the groundwork for the comprehensive standards we see today, which are essential for ensuring that ICs can function reliably in a wide range of applications.

III. Key Product Standards in IC Development

A. International Standards

1. **International Organization for Standardization (ISO)**: ISO develops and publishes international standards that cover various aspects of IC development, including quality management systems and environmental management.

2. **Institute of Electrical and Electronics Engineers (IEEE)**: IEEE standards focus on electrical and electronic engineering, providing guidelines for design, testing, and performance metrics for ICs.

3. **International Electrotechnical Commission (IEC)**: IEC standards address safety and performance in electrical and electronic devices, ensuring that ICs can operate safely in various environments.

B. National Standards

1. **American National Standards Institute (ANSI)**: ANSI coordinates the development of American national standards, including those relevant to ICs, ensuring they meet specific quality and safety requirements.

2. **European Committee for Electrotechnical Standardization (CENELEC)**: CENELEC develops standards for electrical and electronic products in Europe, promoting safety and interoperability.

C. Industry-Specific Standards

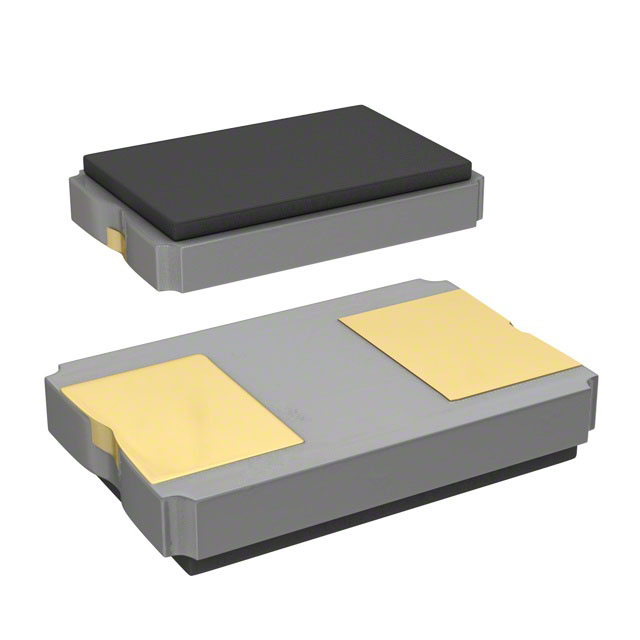

1. **JEDEC Solid State Technology Association**: JEDEC is a key player in developing standards for semiconductor technology, including memory and microelectronics, ensuring compatibility and performance.

2. **IPC Standards for Printed Circuit Boards**: IPC standards focus on the design and manufacturing of printed circuit boards (PCBs), which are essential for integrating ICs into electronic devices.

IV. Categories of Product Standards

A. Design Standards

1. **Design for Manufacturability (DFM)**: DFM standards ensure that IC designs can be efficiently manufactured, reducing production costs and time.

2. **Design for Testability (DFT)**: DFT standards facilitate the testing of ICs, ensuring that they can be effectively evaluated for performance and reliability.

B. Performance Standards

1. **Speed and Frequency Specifications**: These standards define the operational speed and frequency ranges for ICs, ensuring they can meet the demands of modern applications.

2. **Power Consumption and Thermal Management**: Standards in this category address the power efficiency of ICs and the management of heat generated during operation, which is critical for maintaining performance and reliability.

C. Reliability Standards

1. **Failure Rate and Mean Time Between Failures (MTBF)**: These standards provide metrics for assessing the reliability of ICs, helping manufacturers predict product lifespan and performance.

2. **Environmental Testing Standards**: These standards ensure that ICs can withstand various environmental conditions, such as temperature fluctuations and humidity, which can impact performance.

D. Safety Standards

1. **Electrical Safety Standards**: These standards ensure that ICs operate safely, minimizing the risk of electrical hazards.

2. **Electromagnetic Compatibility (EMC) Standards**: EMC standards ensure that ICs can operate without causing or being affected by electromagnetic interference, which is crucial for maintaining functionality in complex electronic systems.

V. Compliance and Certification Processes

A. Importance of Compliance

Compliance with product standards is essential for manufacturers to ensure that their ICs are safe, reliable, and effective. Non-compliance can lead to product failures, safety hazards, and legal liabilities, making adherence to standards a critical aspect of IC development.

B. Certification Bodies and Their Roles

Various certification bodies, such as Underwriters Laboratories (UL) and the International Electrotechnical Commission (IEC), play a vital role in evaluating and certifying ICs against established standards. These organizations provide independent assessments, ensuring that products meet the necessary criteria for safety and performance.

C. Steps in the Certification Process

1. **Pre-certification Testing**: Before formal certification, ICs undergo rigorous testing to identify any potential issues that may affect compliance.

2. **Documentation and Reporting**: Manufacturers must provide detailed documentation of their testing processes and results, demonstrating compliance with relevant standards.

3. **Post-certification Surveillance**: After certification, ongoing surveillance ensures that manufacturers continue to meet standards throughout the production lifecycle.

VI. Challenges in Meeting Product Standards

A. Rapid Technological Advancements

The pace of technological change in the IC industry presents significant challenges for standardization. As new technologies emerge, existing standards may become outdated, necessitating continuous updates and revisions.

B. Globalization and Diverse Standards

With the globalization of the electronics market, manufacturers must navigate a complex landscape of differing national and international standards. This diversity can complicate compliance efforts and increase costs.

C. Balancing Cost and Compliance

Achieving compliance with product standards often requires significant investment in testing, documentation, and quality assurance processes. Manufacturers must balance these costs with the need to remain competitive in a rapidly evolving market.

VII. Future Trends in IC Product Standards

A. Emerging Technologies and Their Impact

As technologies such as 5G, Internet of Things (IoT), and artificial intelligence continue to evolve, new standards will be required to address the unique challenges and requirements of these applications.

B. The Role of Artificial Intelligence and Machine Learning

AI and machine learning are increasingly being integrated into IC design and testing processes, potentially leading to the development of new standards that leverage these technologies for improved performance and efficiency.

C. Sustainability and Environmental Considerations

As environmental concerns grow, there is a push for standards that promote sustainability in IC development. This includes standards for energy efficiency, waste reduction, and the use of environmentally friendly materials.

VIII. Conclusion

Product standards play a crucial role in the development of integrated circuits, ensuring that they meet the necessary criteria for performance, reliability, and safety. As the industry continues to evolve, the importance of these standards will only increase. Manufacturers, industry organizations, and regulatory bodies must work together to adapt to emerging technologies and address the challenges of globalization and rapid technological advancements. By prioritizing compliance with product standards, stakeholders can contribute to the continued success and innovation of the integrated circuit industry.

IX. References

A. List of Relevant Standards Organizations

- International Organization for Standardization (ISO)

- Institute of Electrical and Electronics Engineers (IEEE)

- International Electrotechnical Commission (IEC)

- American National Standards Institute (ANSI)

- European Committee for Electrotechnical Standardization (CENELEC)

- JEDEC Solid State Technology Association

- IPC Standards

B. Academic and Industry Publications

- IEEE Journals

- Journal of Semiconductor Technology and Science

- Electronics Weekly

C. Online Resources for Further Reading

- ISO website: www.iso.org

- IEEE website: www.ieee.org

- JEDEC website: www.jedec.org

This comprehensive overview of product standards for integrated circuit development highlights the critical role these standards play in ensuring the safety, reliability, and performance of ICs in an ever-evolving technological landscape.