How does a chip integrated circuit work?

How Does a Chip Integrated Circuit Work?

I. Introduction

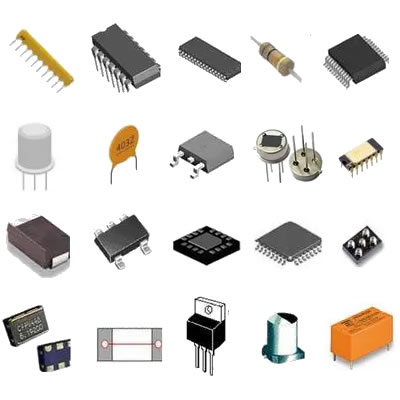

Integrated Circuits (ICs) are the backbone of modern electronics, enabling the functionality of countless devices we use daily. From smartphones to medical equipment, ICs are essential for processing information and controlling electronic systems. This article aims to demystify how integrated circuits work, exploring their historical development, basic components, structure, fabrication processes, functionality, applications, and future trends.

II. Historical Background

The journey of integrated circuits began with the evolution of electronic components. Before ICs, electronic devices relied on discrete components like resistors, capacitors, and transistors, which were bulky and inefficient. The invention of the integrated circuit in the late 1950s revolutionized electronics by allowing multiple components to be fabricated on a single chip of semiconductor material.

Key figures in this development include Jack Kilby, who created the first working IC in 1958, and Robert Noyce, who independently developed a similar concept shortly after. Their innovations laid the groundwork for the semiconductor industry, leading to significant milestones such as the introduction of the microprocessor in the 1970s, which further propelled the digital revolution.

III. Basic Components of Integrated Circuits

Integrated circuits are composed of several fundamental components, each playing a crucial role in their operation.

A. Transistors

Transistors are the building blocks of ICs, functioning as switches or amplifiers. There are two primary types of transistors used in ICs: Bipolar Junction Transistors (BJTs) and Metal-Oxide-Semiconductor Field-Effect Transistors (MOSFETs). BJTs are known for their ability to amplify current, while MOSFETs are favored for their efficiency and speed, making them ideal for digital applications.

B. Resistors

Resistors are used in ICs to control the flow of electric current. They help set the operating conditions for transistors and other components. Various types of resistors, such as thin-film and thick-film resistors, are utilized in ICs, each offering different characteristics suited for specific applications.

C. Capacitors

Capacitors store electrical energy and release it when needed. In ICs, they play a vital role in timing applications, filtering signals, and stabilizing power supplies. Capacitors can be found in various forms, including ceramic and tantalum capacitors, each chosen based on the circuit's requirements.

D. Diodes

Diodes are semiconductor devices that allow current to flow in one direction only, providing essential functions such as rectification and voltage regulation. Different types of diodes, including Zener diodes and Schottky diodes, are used in ICs to manage current flow and protect against voltage spikes.

IV. Structure of Integrated Circuits

The structure of an integrated circuit is a complex arrangement of layers and components.

A. Layers of an IC

An IC typically consists of several layers:

1. **Substrate**: The base layer, usually made of silicon, provides mechanical support and electrical insulation.

2. **Dielectric Layers**: These insulating layers separate different conductive paths and prevent short circuits.

3. **Metal Interconnects**: These layers connect various components within the IC, allowing for signal and power distribution.

B. Chip Design and Layout

The design of an IC is a meticulous process that involves creating a schematic representation of the circuit. Computer-Aided Design (CAD) tools are essential in this phase, enabling engineers to simulate and optimize the layout before fabrication. The design must consider factors such as component placement, signal integrity, and thermal management to ensure optimal performance.

V. Fabrication Process of Integrated Circuits

The fabrication of integrated circuits is a highly sophisticated process that involves several key steps.

A. Overview of Semiconductor Manufacturing

Semiconductor manufacturing begins with the preparation of silicon wafers, which serve as the substrate for ICs. The process requires a cleanroom environment to prevent contamination, as even microscopic particles can affect the performance of the final product.

B. Key Steps in IC Fabrication

1. **Wafer Preparation**: Silicon wafers are sliced from a larger crystal and polished to create a smooth surface.

2. **Photolithography**: A light-sensitive photoresist is applied to the wafer, and ultraviolet light is used to transfer the circuit pattern onto the photoresist.

3. **Etching**: The exposed areas of the photoresist are removed, and the underlying silicon is etched away to create the desired patterns.

4. **Doping**: Impurities are introduced into the silicon to modify its electrical properties, creating regions of n-type and p-type semiconductors.

5. **Metallization**: Metal layers are deposited to form interconnections between components.

C. Quality Control and Testing

After fabrication, ICs undergo rigorous testing to ensure they meet performance standards. This includes functional testing, thermal testing, and reliability assessments to identify any defects before they are packaged and shipped.

VI. Functionality of Integrated Circuits

Integrated circuits process information through a combination of logic gates and data flow mechanisms.

A. How ICs Process Information

Logic gates, the fundamental building blocks of digital circuits, perform basic operations such as AND, OR, and NOT. These gates are combined to create complex circuits capable of executing arithmetic operations, data storage, and control functions.

B. Types of Integrated Circuits

ICs can be categorized into several types:

1. **Analog ICs**: These handle continuous signals and are used in applications like audio amplification and signal processing.

2. **Digital ICs**: These process discrete signals and are essential for computing and digital communication.

3. **Application-Specific ICs (ASICs)**: Designed for specific applications, ASICs optimize performance and efficiency for tasks like video processing or telecommunications.

4. **Microcontrollers and Microprocessors**: These are integrated circuits that contain a CPU, memory, and input/output peripherals, enabling them to perform complex tasks in embedded systems.

VII. Applications of Integrated Circuits

Integrated circuits have a wide range of applications across various industries:

A. Consumer Electronics

ICs are integral to devices like smartphones, tablets, and televisions, enabling features such as touchscreens, wireless communication, and high-definition displays.

B. Telecommunications

In telecommunications, ICs facilitate data transmission, signal processing, and network management, supporting technologies like 5G and satellite communication.

C. Automotive Industry

Modern vehicles rely on ICs for engine control, safety systems, infotainment, and navigation, enhancing performance and driver experience.

D. Medical Devices

ICs are crucial in medical devices, enabling functions such as patient monitoring, diagnostic imaging, and therapeutic equipment, improving healthcare outcomes.

E. Industrial Automation

In industrial settings, ICs control machinery, manage processes, and enable automation, increasing efficiency and productivity.

VIII. Future Trends in Integrated Circuit Technology

The future of integrated circuits is promising, with several trends shaping their development.

A. Advancements in Miniaturization (Moore's Law)

Moore's Law, which predicts the doubling of transistor density on a chip approximately every two years, continues to drive innovation. As transistors become smaller, ICs can perform more functions while consuming less power.

B. Emerging Materials and Technologies

Research into new materials, such as graphene and carbon nanotubes, holds the potential to enhance the performance of ICs. Additionally, advancements in quantum computing may revolutionize how information is processed, leading to unprecedented computational capabilities.

C. Challenges and Opportunities

Despite the exciting prospects, the semiconductor industry faces challenges, including rising manufacturing costs, supply chain disruptions, and the need for sustainable practices. However, these challenges also present opportunities for innovation and growth in the field.

IX. Conclusion

Integrated circuits are a cornerstone of modern technology, enabling the functionality of countless devices that shape our daily lives. From their historical development to their intricate design and fabrication processes, ICs represent a remarkable achievement in engineering and innovation. As technology continues to evolve, the impact of integrated circuits on society will only grow, paving the way for new applications and advancements in various fields.

X. References

For further exploration of integrated circuits and semiconductor technology, consider the following resources:

1. "Microelectronics: An Introduction to the Design and Fabrication of Integrated Circuits" by David A. Hodges and Horace G. Jackson.

2. "Semiconductor Physics and Devices" by Donald A. Neamen.

3. IEEE Xplore Digital Library for academic papers on integrated circuits and semiconductor technology.

4. Online courses and tutorials on IC design and fabrication from platforms like Coursera and edX.

This comprehensive overview of integrated circuits highlights their significance, functionality, and future potential, providing a solid foundation for understanding this critical aspect of modern technology.